Material choice and innovations in metal cutting are supporting the transition to more environmentally friendly vehicles. And, demand for vehicles is increasing.

According to a report by the International Transport Forum, global transport activity is expected to double by 2050 compared to 2015 levels. Producing more vehicles to meet increasing demand is inevitable — the real challenge is making them greener. The International Energy Agency (IEA) reports that transport already accounts for 24% of direct CO2 emissions from fuel combustion, with road vehicles accounting for nearly three-quarters of this figure.

The EV evolution

Among zero-emission modes of transport are electric vehicles (EVs), which executive director at the IEA, Fatih Birol, said, “have an indispensable role to play in reaching net-zero emissions worldwide.” By using electricity, especially when from sustainable resources, from the grid to recharge batteries that power an electric motor, EVs produce zero tailpipe emissions and are thus a more environmentally friendly option than internal combustion engine vehicles.

According to the IEA’s Global EV Outlook 2021 report, there were ten million electric cars on the world’s roads at the end of 2020, and EV registrations increased by 41% that year. While EVs are clearly on the rise, their adoption can be accelerated further by overcoming concerns that the EV vehicles have an insufficient range between charges.

And the range is not just the responsibility of the battery. In addition to more robust charging infrastructure and improvements to EV battery design, every element of a vehicle needs to be made lighter. An EV with a lower weight requires less energy to travel resulting in a greater range on a single charge. If the vehicle weight is reduced by 20%, the vehicle should be able to travel around 20% further on the same charge.

Aluminum plays a large role in the light-weighting of EVs, weighing just a fraction of the more traditional automotive materials of choice — steel or cast irons. Aluminum is now commonly selected for a range of vehicle parts, such as chassis, internal panels, motor housing, and battery enclosures.

Mastering machining

However, components made from aluminum are notoriously more difficult to machine. Aluminum is softer than most metals, which can make it challenging to work with. What’s more, the melting point of stainless steel is 1510 degrees Celsius, whereas for aluminum it’s 660 degrees Celsius.

When machining the metal, the lower melting temperature of aluminum means that chips can build up from the heat of friction at high speeds and adhere to the tool. This chip accumulation can dull the tool, making it difficult to cut through the billet. In addition, manufacturers can face issues such as time-consuming tool setups, inconsistent tool wear, burr formation, and inferior surface finishes. The need for high speeds is also a struggle.

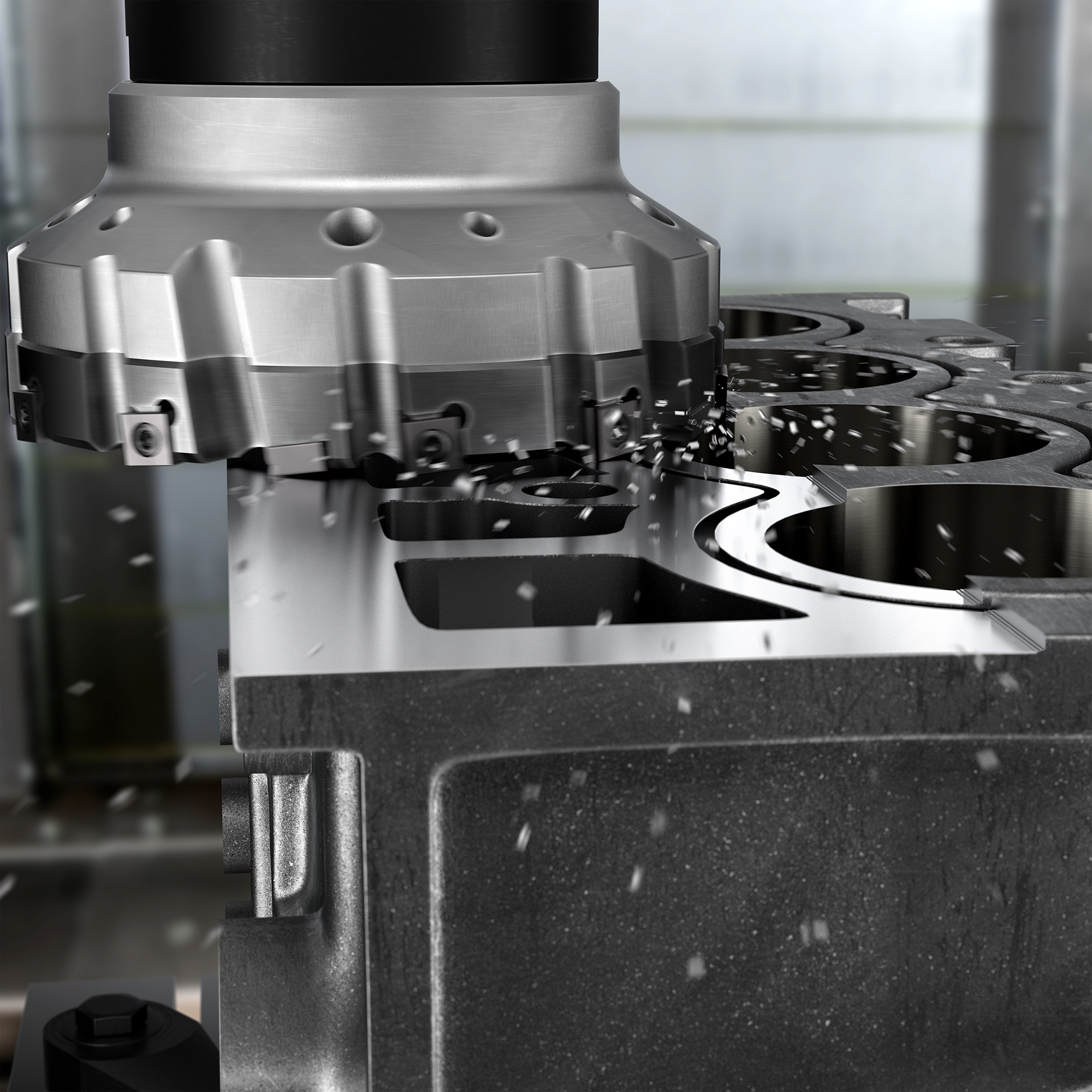

Fortunately, these challenges can be overcome by selecting a tool with an optimized design that’s made from advanced materials. For instance, the Sandvik Coromant M5C90 face milling tool, part of its M5 cutter series, was designed for solid aluminum parts with long milling operations, as well as for roughing and finishing cylinder heads, blocks, and electric car components.

In just one efficient operation, the M5C90 can perform the entire machining process, from roughing to finishing. In many cases, this can be with a depth of cut of up to four millimeters. This tool can increase tool life by fivefold and reduce cycle time by up to 200%.

In addition, the M5 cutter series features step technology, where its extremely hard-wearing polycrystalline diamond (PCD) inserts are arranged in a spiral and staggered vertically to remove material from the workpiece, both axially and radially. Furthermore, the last tooth has wiper geometry to further ensure a high-quality, flat-surface finish. The wiper cutting edge remains in a fixed position, which eliminates the need for time-consuming setups. Other tools in the M5 series include the M5B90 face milling cutter concept for fine finishing and the M5F90 combination milling cutter for roughing and finishing in smaller dimensions.

The transition to EVs will lower transport emissions, and adoption can be accelerated by increasing their efficiency. EVs that take advantage of aluminum components can travel further per charge, helping to overcome range anxiety. Automotive manufacturers who select machining tools optimized for aluminum will be able to produce high-quality aluminum EV components ― helping to support the shift to greener travel.

For more information visit www.sandvik.coromant.com.

Contact Details

Related Glossary Terms

- burr

burr

Stringy portions of material formed on workpiece edges during machining. Often sharp. Can be removed with hand files, abrasive wheels or belts, wire wheels, abrasive-fiber brushes, waterjet equipment or other methods.

- cast irons

cast irons

Cast ferrous alloys containing carbon in excess of solubility in austenite that exists in the alloy at the eutectic temperature. Cast irons include gray cast iron, white cast iron, malleable cast iron and ductile, or nodular, cast iron. The word “cast” is often left out.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.