Kitagawa North-Tech Inc. acquires exclusive distribution

Kitagawa North-Tech Inc. acquires exclusive distribution

Schaumburg, IL – August 13, 2018 – Kitagawa NorthTech, Inc., a specialist in Standard Power Chucks, Advanced and Custom Engineered Workholding, has acquired the exclusive distribution, sales and marketing rights for Kawatatec Nobel branded chucks for North America.

Schaumburg, IL – August 13, 2018 – Kitagawa NorthTech, Inc., a specialist in Standard Power Chucks, Advanced and Custom Engineered Workholding, has acquired the exclusive distribution, sales and marketing rights for Kawatatec Nobel branded chucks for North America. Due to their rugged build and extremely large size, the Nobel brand of Chucks now available from Kitagawa NorthTech have become synonymous with Oil & Gas industry applications over the last three decades. Nobel Chucks are popular in oil and gas country applications because of their unique features, forged steel bodies, large bore size, time-tested performance and reliability in these demanding applications.

Available up to 3.5 Meters (11.48') in size, Kitagawa NorthTech's Nobel Chucks, Face Plates and Oil Country Chucks Serve a Wide Range of Applications

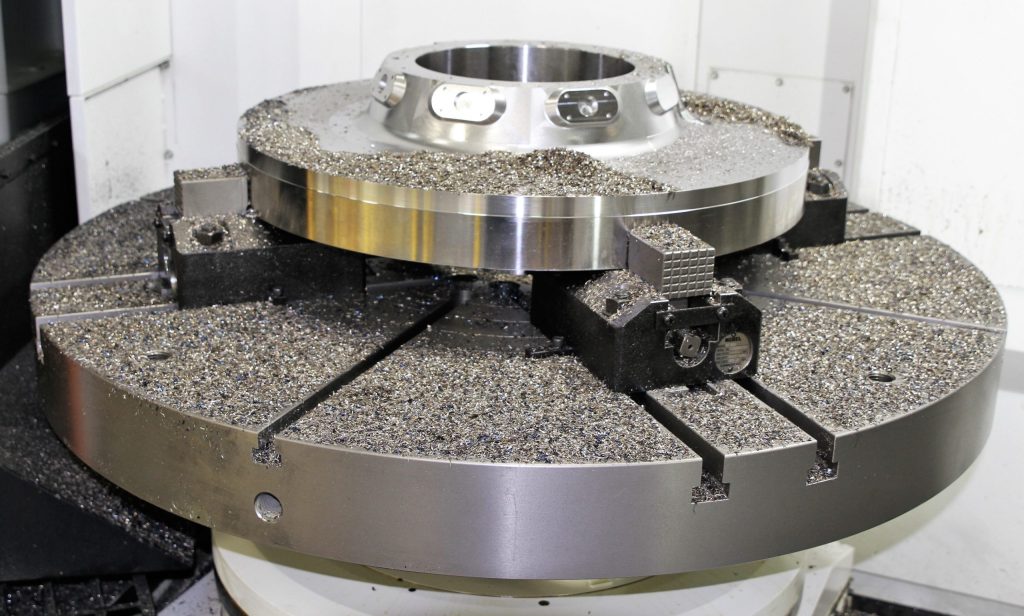

The Nobel Large Power, Manual & Special VTL Face Plates and Chucks are designed for Large Bearing, Aerospace, Power Generation and large Commercial work, while the Nobel Oil Country Chucks are uniquely suited for Down-Hole Drilling, Instrumentation, Fracking & Refining.

Kitagawa NorthTech Nobel Chucks are also available in a wide assortment of sizes, styles and configurations including large Face Plates with Boring Mill Jaws, manual Independent 4 Jaw, 3 Jaw Scroll, Power Combination Chucks, Indexing Chucks, Pull Down Chucks and Special Application 6 Jaw 2+2+2 Chucks for thin wall machining up to 3.5 meters. The Kitagawa NorthTech Nobel Special Large Bore Oil and Gas Chucks up to 42" diameter can handle spindle pass through of up to 14.5" diameter.

Kevin Bennett, VP of Sales & Marketing adds, "Kitagawa and Kawatatec are two like-minded companies. We both share a similar heritage and approach to design, manufacturing principles and quality standards, so we believed the Nobel brand to be an excellent addition to join our ever expanding family of Workholding Solutions. Our comprehensive family also includes, standard, advanced and engineered workholding and custom engineered workholding solutions for rotational, stationary, grinding, turning and milling. Acquiring the Nobel brand distribution rights for North America also reinforces our vision and promise to customers to be their turnkey workholding supplier in North America."

Kitagawa NorthTech earlier this year absorbed ITEX Workholding operations, which previously held the distribution rights for Nobel Chucks in North America. Principal of ITEX, Mike Roberts joined Kitagawa NorthTech, Inc to provide continuity in selling Nobel products, along with his tremendous knowledge and breadth of oil & gas industry experience. He currently serves as Regional Sales Manager for Kitagawa NorthTech throughout the Southwest.

Nobel Brand Chucks from Kitagawa NorthTech Complete Large Diameter VTL Workholding Offering

With the addition of Nobel brand chucks, Kitagawa NorthTech offers the most comprehensive family of VTL Workholding solutions available in the industry. The family includes Manual and Power Wrench Scroll Chucks, 4 Jaw Independent Chucks, Incredibly Large 6 Jaw Pin Arbor PullDown Chucks, Large 6 Jaw 2+2+2 Thin Wall Ring Application Chucks, Combination Power/Boring Mill Jaw Chucks and Face Plates with Boring Mill Jaws. They also offer Large Manual and Hydraulic Part Specific VTL Turning Fixtures.