Simmons Machine Tool upgrades capacity with new 5-axis mill

Simmons Machine Tool upgrades capacity with new 5-axis mill

Railway machine tool builder needed a robust 5-axis machine to ensure uptime, accuracy, and precision in cutter tool manufacturing

Simmons Machine Tool Corp., a machine tool builder for the railway industry, needed to upgrade its production capacity and was investigating 5-axis mill-turn machining centers to achieve this goal.

Simmons Machine Tool Corp., a machine tool builder for the railway industry, needed to upgrade its production capacity and was investigating 5-axis mill-turn machining centers to achieve this goal.

The Albany, NY, based company, part of the NSH Group, had stringent standards when it came to issues such as chip fall, robustness, accuracy, and consistency, and scanned the market looking for 5-axis machines to meet its needs. After initially reviewing the market for machines used in the tool-and-die mold market, the company ultimately decided to purchase a GROB G550T 5-axis universal mill-turn machining center from Grob, a German company with U.S. offices in Bluffto, Ohio, as the machine was built for highly demanding manufacturing applications.

Machining for machine tools

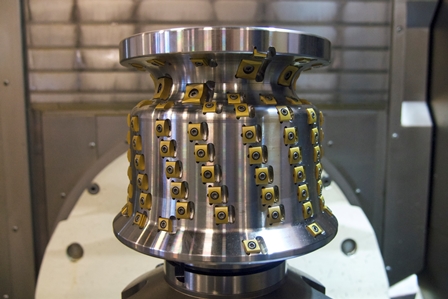

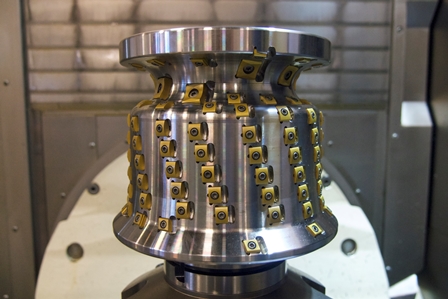

Simmons needed a 5-axis machine to turn and mill precise products such as its profile milling cutters for underfloor wheel re-profiling machines. The company turns and mills these cutters from 12" diameter solid stock 4150 steel, hardened to about 300 BHN. The cutters are then used on Simmons' Stanray machines, supplied to freight railway, metro, and transit passenger railway customers around world.

Weighing 22.5 tons, the Stanray machine is mounted in a pit under the rail so that a locomotive can be positioned on top of the machine. The profile milling cutters then re-profile the wheels, which are often in poor condition with flat spots on the tread caused by wheel slippage or emergency braking. The flat spots, which are work hardened areas about the size of a quarter, are for higher in measured hardness compared to the rest of the wheel surface. The cutters themselves, then, must be extremely robust, just as the machines that produce them must be.

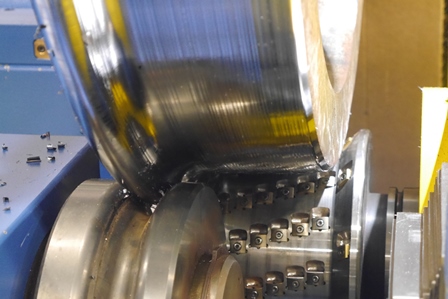

"We reviewed several different 5-axis machines, and most couldn't keep up with the demands of our application," said David William Davis, company president and COO. "We make a lot chips when we make a cutter, so chip containment and evacuation from the machine tool is important, and many just didn't measure up."

"We reviewed several different 5-axis machines, and most couldn't keep up with the demands of our application," said David William Davis, company president and COO. "We make a lot chips when we make a cutter, so chip containment and evacuation from the machine tool is important, and many just didn't measure up."

The company found that 5-axis machining centers with vertical spindle orientations tended to have more surfaces and areas for chips to collect on, which prevented easy chip evacuation. Additionally, many 5-axis machines were focused on die and mold production rather than heavy duty metal cutting, and so couldn't hold up to the railway machine application.

"Overall machine robustness and dependability was also an issue, primarily involving spindle bearing contamination and related failures," Davis added. "Last, we found that with many 5 axis machine builders, locally available service plus quality remote or virtual service was often simply not available."

Finding a good fit with GROB

After rejecting several 5-axis machines with vertical spindle orientations that did not meet its needs, the team at Simmons met with a representative from GROB, who presented the company's horizontal spindle 5-axis universal mill-turn machines.

Simmons chose GROB's 5-axis machining technology that has a horizontal spindle configuration allowing for optimal chip flow, features intuitive programming, and delivers consistency and accuracy.

Davis said a key reason for purchasing the GROB 5-axis machine was the horizontal spindle axis. "The horizontal spindle configuration, plus the overall design of the machining area, permits optimal chip flow and evacuation and unattended running, all of which are extremely important in our manufacturing processes."

In addition, he said the machine can achieve better dimensional consistency with the G550T. As an example, one key dimension on the Stanray profile milling cutter has to be turned to +0.0000, -0.0005". "After a short time using the G550T, we simply eliminated probing this feature because our confidence in hitting this dimension repeatedly is so high," Davis said.

Saving time, saving money

Implementing GROB's 5-axis machining technology has translated into cost savings and efficiency benefits. Downtime was dramatically reduced, since the GROB G550T is built to withstand the demands of Simmons' manufacturing processes and materials. Given that they are used to machine consumable parts, the G550T's design factors for uptime are important to manufacturing efficiency and cost optimization. In addition, the GROB machine can be operated unattended.

Another important ingredient for meeting and exceeding ROI goals has been the G550T's accuracy and consistency; the machine is so accurate that individual components do not need to be measured for accuracy, thus reducing measuring time as well as non-value-added time in the production stream. In addition, reduced vibration at the tool tip translates into extended tool life, accuracy, and consistency, the company says.

As a company that builds machine tools, Simmons was uniquely positioned as a machine tool building seeking equipment from another machine tool builder to enable accurate and efficient tool manufacturing. The company had stringent standards when they researched 5-axis machines and were seeking a 5-axis machine that could keep up with difficult materials and processes. After extensive research, the company purchased the GROB G550T 5-axis universal mill-turn machining center that offered benefits in terms of chip fall and evacuation, service, intuitive programming, and exceptional reliability and consistency.