Throwback Thursday: History of Tools

Throwback Thursday: History of Tools

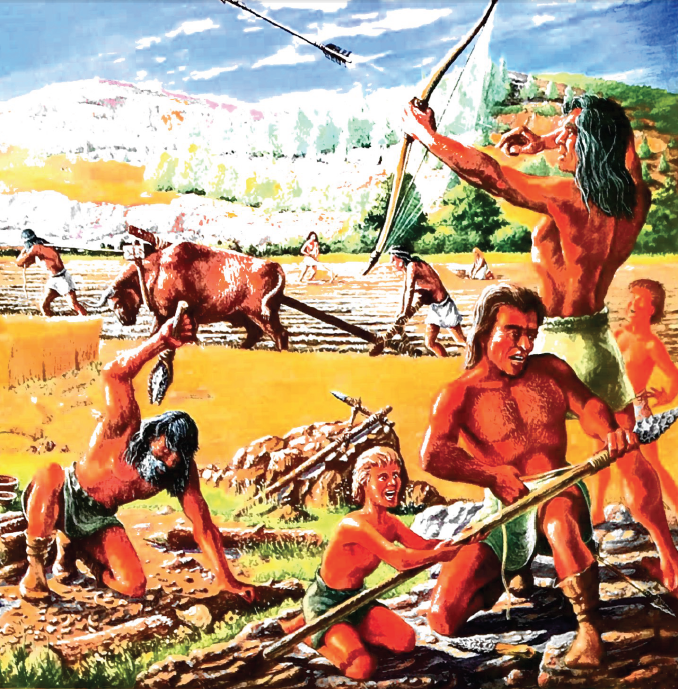

With the August 1985 issue, Cutting Tool Engineering launched a decade-long series of articles titled, "History of Tools." The first installment, which you can download and read by clicking here, began as the ultimate Throwback Thursday endeavor: urging readers with their eyes on the future to recall the machine tool industry's humble beginnings. So, yeah, The Stone Age.

With the August 1985 issue, Cutting Tool Engineering launched a decade-long series of articles titled, "History of Tools." The first installment, which you can download and read by clicking here, began as the ultimate Throwback Thursday endeavor: urging readers with their eyes on the future to recall the machine tool industry's humble beginnings. So, yeah, The Stone Age.

With the August 1985 issue, Cutting Tool Engineering launched a decade-long series of articles titled, "History of Tools." The first installment, which you can download and read by clicking here, began as the ultimate Throwback Thursday endeavor: urging readers with their eyes on the future to recall the machine tool industry's humble beginnings. So, yeah, The Stone Age.

Though written by the CTE editorial staff at the time, the series relied on the research of Leighton Wilkie, an inventor, author and founder of the DoAll Sawing Products company. Wilkie, who invented and manufactured the first metal cutting band saw in 1933, established a non-profit organization—the Wilkie Brothers Foundation—in 1953. Through that foundation, he supported anthropological expeditions and sponsored various educational exhibits, including one for the Museum of Science and Industry in Chicago titled, "Civilization Through Tools."

In 1985, CTE sought and received permission from the Wilkie Brothers Foundation to adapt much of Leighton Wilkie's research for the "Civilization Through Tools" exhibit into articles for the History of Tools series.

The one-page article set the context for the series: "As we prepare for the 21st Century, space shuttles to the moon and beyond are no longer something out of Buck Rogers comics, but are everyday realities. Sophisticated machines are producing a comfortable existence that was only dreamed of just a few decades ago, but today they are taken for granted. However, to have achieved this millenium, we had to start from a very basic existence."

Click on the following covers or links to read the first four installments of the History of Tools series, which covers the evolution of tools from The Stone Age to the Industrial Revolution.