United Grinding’s C.O.R.E. shown at Evolution to Revolution event

United Grinding’s C.O.R.E. shown at Evolution to Revolution event

United Grinding North America opened its doors for Evolution to Revolution, a precision CNC grinding industry event filled with live machine demonstrations, technology innovations, breakout discussion sessions and keynote presentations from some of the industry's best-known companies.

United Grinding North America opened its doors for Evolution to Revolution, a precision CNC grinding industry event filled with live machine demonstrations, technology innovations, breakout discussion sessions and keynote presentations from some of the industry's best-known companies.

United Grinding North America opened its doors for Evolution to Revolution, a precision CNC grinding industry event filled with live machine demonstrations, technology innovations, breakout discussion sessions and keynote presentations from some of the industry's best-known companies.

Along with an 11-station display of part-production and automation solutions, the company also unveiled its Customer Oriented REvolution (C.O.R.E.) technology, and celebrated their recently announced partnership with TITANS of CNC.

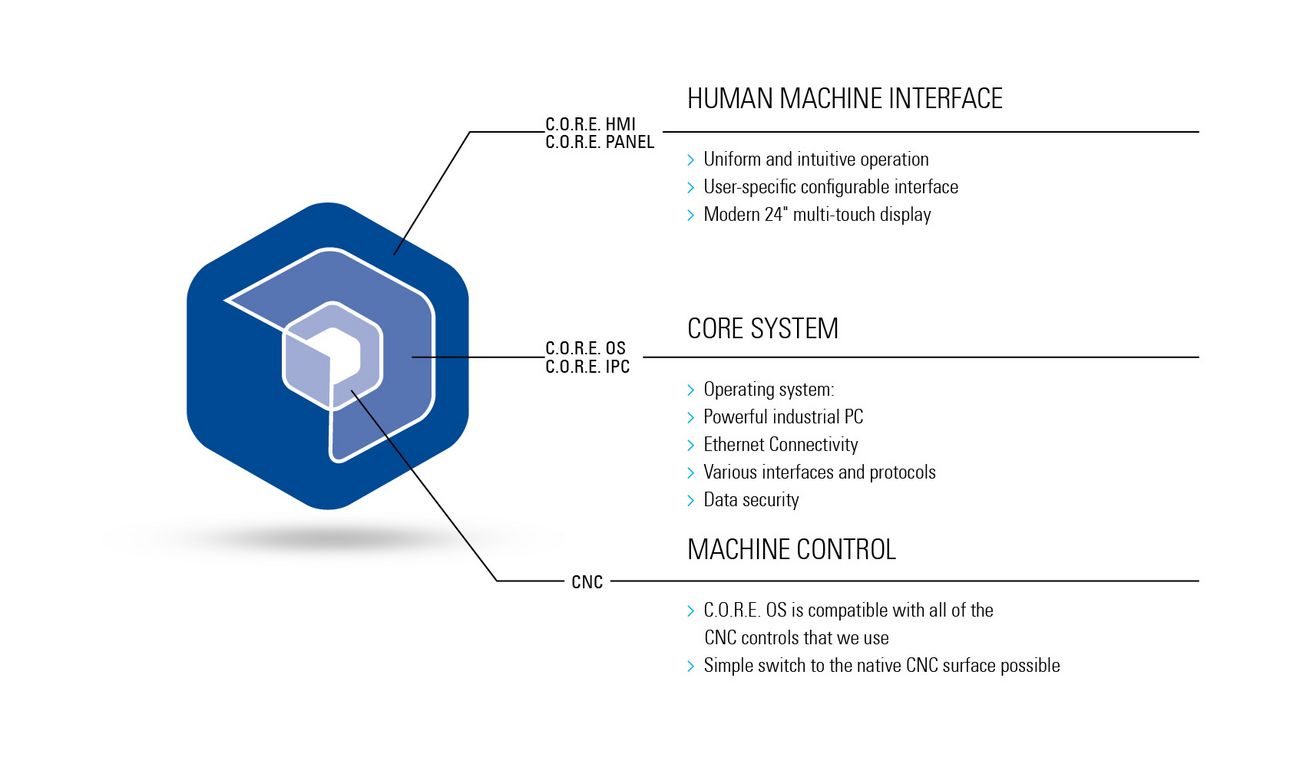

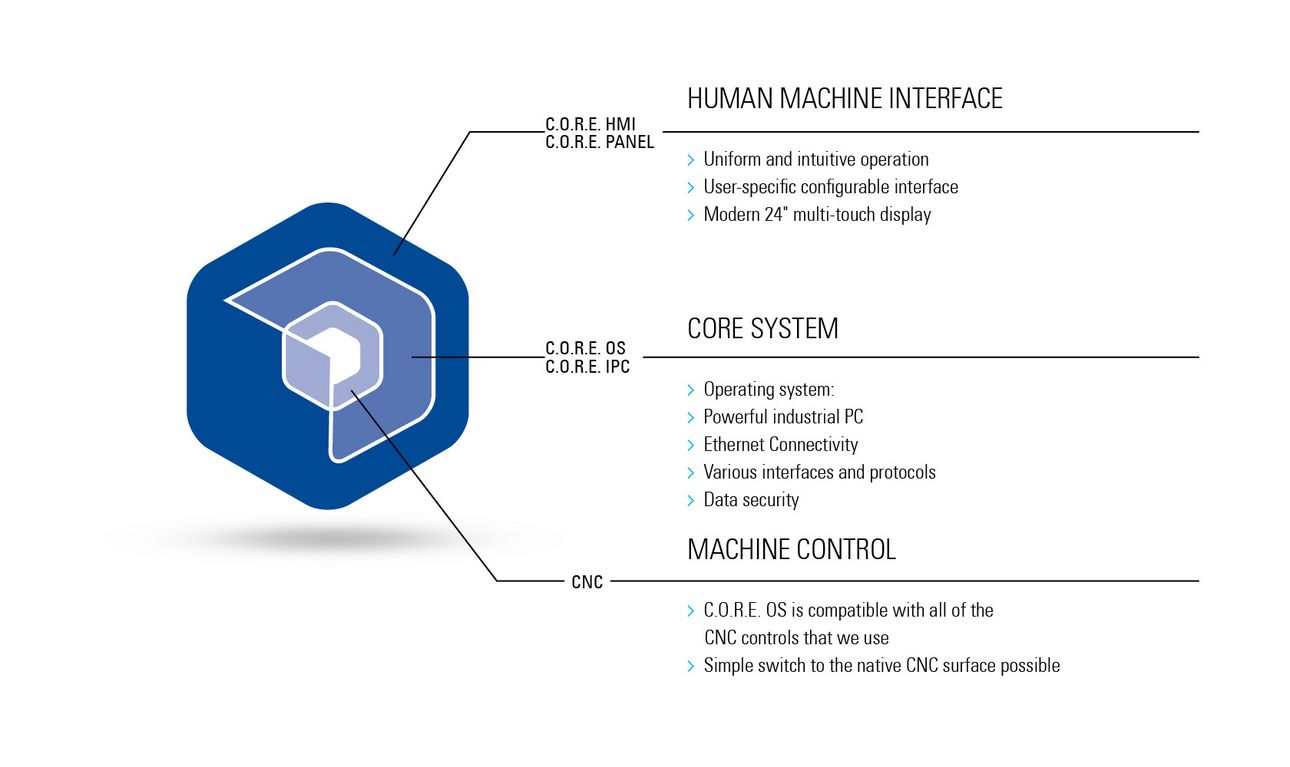

Developed after years of research and development led by the United Grinding Group and incorporating collaborative efforts from engineering teams across all eight United Grinding machine tool brands, C.O.R.E. technology adds next-generation productivity, adaptability and versatility to grinding applications.

Thanks to the uniform C.O.R.E. software architecture, exchanging data between United Grinding machines is easy. The integrated umati interface can be used to communicate with third-party systems. It also offers access to United Grinding Digital Solutions products directly on the machine, without requiring the installation of supplemental hardware. C.O.R.E. not only establishes the technical foundation for this and other IoT and data applications, it also forms the basis of revolutionary yet uniform operation.

In addition to C.O.R.E., United Grinding North America also demonstrated its versaLoad machine-tending automation solution that delivers easy-to-use, highly flexible part loading, especially for the high-mix, low-volume jobs that dominate the production line in many shops.

Including live demonstrations of grinding and automation solutions, United Grinding North America presented 15 educational seminars. These mini events showcased topics such as application-specific approaches to manufacturing challenges and the benefits of rebuilding older grinding machines to regain performance or serve as a trade-in on the purchase of newer technologies. United Grinding Digital Solutions rounded out the presentations with compelling examples of the use of networked data insights to enhance machine performance and overall shop productivity.

Speakers from some of the grinding industry's best known product manufacturers, Norton | Saint-Gobain Abrasives, Oelheld, Blaser Swisslube, Marposs, and Haimer also took to the main stage, with Scott Leoncini from TITANS of CNC delivering the keynote speech on the second day. Scott's presentation, titled, "Rising to Greatness: How TITANS of CNC is Engaging and Educating the Next Generation of the Manufacturing Worker" focused on the future of manufacturing. Titan Gilroy also made an appearance in the presentation on C.O.R.E. technology.

Machines on display at the event included the following:

- BLOHM PROFIMAT MC Aero

- BLOHM PROFIMAT XT

- MÄGERLE MFP 30

- STUDER favorit w/ versaLoad

- STUDER S11

- STUDER S31

- STUDER S33

- STUDER S131r

- WALTER HELICHECK 3D

- WALTER HELITRONIC RAPTOR DIAMOND

- WALTER HELITRONIC SL

- WALTER HELTRONIC POWER 400