Industry News

10/09/2020

Jorgensen Conveyors and Filtration Solutions in Mequon, Wisconsin, has made several promotions and a key new hire within its sales and management teams.

10/08/2020

Fastems Group will host an online Open House & Conference entitled "Productivity Beyond Machine Tending" that will showcase the latest developments in automation and surrounding technologies.

10/07/2020

Utilizing the NVision 3D HandHeld laser scanner, a Texas job shop was able to produce highly precise, custom roof racks.

10/06/2020

The F-35 Lightning is one of the most complex and lethal combat fighter jets in the world, and this machine is constructed with thousands of precision components. Starrag machinery are used to produce some of the most complex components on these precision jets.

10/05/2020

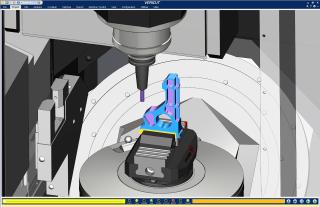

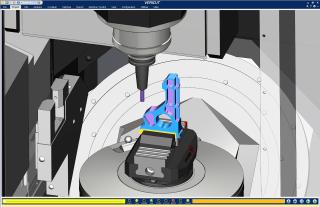

Contract programming houses are an excellent resource for shops with overloaded programming departments, a troublesome project, or are venturing into five-axis territory for the first time. Ron Branch, vice-president of 5th Axis CG Inc. shared valuable insights about machining optimization with Gene Granata, Vericut product manager at CGTech.

10/02/2020

The main driver of business sustainability goals is to make an impact on the environment. Another benefit is the economic value of implementing sustainable actions. Can businesses save money, and protect the planet? Sandvik thinks so.

10/01/2020

When it comes to designing, CAD software has its place, but purchasing and maintaining multiple CAD licenses can be expensive. Kisters offers a solution for supplying CAD to multiple users.

09/30/2020

The Bell Helicopter Drive Systems Center (DSC) in Arlington, Texas, can never be confused with anything “little.” It’s a huge facility, filled with the latest milling, drilling, and boring technologies. In fact, some newly installed equipment is making some of the company's biggest components in its history.

09/30/2020

Industrial automation is changing the way cutting tool manufacturers operate. Machines can take on the heavy lifting at each stage of production letting workers get on with less repetitive tasks. And while automation may sound costly and complex to implement, it’s not reserved just for big business.

09/29/2020

Laser technology was developed in the mid-20th century, and over the decades has emerged as a leading processing method for a broad range of applications. One of the newest uses is for high precision laser micromachining.

09/28/2020

The metal machining, fabrciation and finishing industries must meet EPA and local wastewater requirements for effluent. Under the Clean Water Act, the EPA has identified 65 pollutants and classes of pollutants as “toxic pollutants,” of which 126 specific substances have been designated “priority” toxic pollutants. Failing to meet these requirements can result in severe fines that quickly escalate.

09/28/2020

To contact or not to contact. That is the measurement question. Today, as parts get smaller and more complex, metrology discussions center around contact or non-contact measurement especially as these smaller and more complex components can be damaged by contact with a probe.

09/25/2020

Schunk, a premium tooling and resharpening company in Germany, utilizes state-of-the-art grinding systems and an ANCA workflow RFID system to finish job packets in a chaotic fashion driven by production needs rather than by job order.

09/25/2020

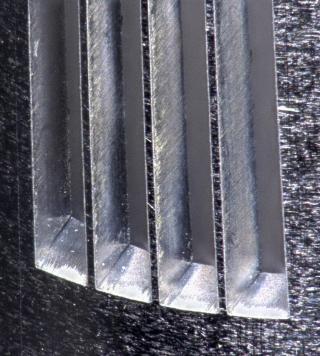

The US cutting tool manufacturer McQuade Industries Inc. has implemented a CNC upgrade program for its roster of 5-axis insert grinders, and the upgrades shaved more than ten minutes per part off the production time of complex geometry cutting tools.

09/24/2020

Registration is now open for Ceratizit’s virtual event that runs from Sept. 30 to Oct. 30, 2020.

09/24/2020

Submarine propellers traditionally take a long time to produce. They are large and have tight tolerances. A Starrag machining center was selecting to produce the 24' propellers.

09/23/2020

Seco Tools LLC has named Brad Andrews has joined Seco North America as Regional Manager – Canada. Brad is responsible for leading the Canadian team and developing and implementing the North America sales strategy to drive growth.

09/23/2020

The larger the series of parts to be produced, the more important cycle times and tool costs are. Designing machinery and tooling through a collaborative design process reduces cycle times and tooling costs, while improving part quality.

09/22/2020

IMCO Carbide Tool Inc., an Ohio-based tool manufacturer, has joined the IMC Group, an international family of metalworking companies that is part of Berkshire Hathaway Inc. conglomerate.

09/21/2020

The Australian Government has ordered the construction of a fleet of 12 regionally superior submarines, known as the Attack Class, for the Royal Australian Navy. A 5-axis gantry machine from The Starrag Group is a critical piece of equipment for the decades-long project.