Industry News

03/19/2020

Guards on grinding machines are particularly important for ensuring operator safety. Grinding wheels seldom burst, but when they do, there is a great risk of serious injury to the machine operator. Recent studies suggest, however, that the enclosures commonly used in gear grinding machines, for example, could be overdesigned at present. Investigations conducted by the VDW (Verein Deutscher Werkzeugmaschinenfabriken – German Machine Tool Builders' Association) and the Institute of Machine Tools and Factory Management (IWF) at TU Berlin reveal that it is possible to use safety guards which are up to 70% thinner, depending on the width of the grinding wheel. These findings are leading to changes in ISO standardization.

03/16/2020

No one can predict the future of manufacturing, but those who supply tooling, software or equipment are closer to the ins and outs of the manufacturing industry than most. This gives them an almost prescient ability to forecast what’s coming down the pipe, offer recommendations on what manufacturers need to be successful in these turbulent times and help machine shops and fabricators understand which technologies will bring them the greatest bang for the buck.

03/13/2020

Birmingham, Alabama-based Motion Industries Inc., a leading distributor of maintenance, repair and operation replacement parts, has promoted Greg Cook to executive vice president and chief financial officer, effective April 1, 2020.

03/12/2020

Of unique importance today is the role of post-process metrology to validate the integrity of AM builds. One specific reason for this importance is that many parts produced by AM end up in safety critical applications where end-use functionality is of vital importance. The nature and relative roughness of AM surfaces, whether analyzing individual layers within a build, or the surface of a finished part render conventional metrology solutions somewhat impotent. In this article, I review developments from Zygo including work alongside Richard Leach that allow for hitherto unattainable metrology results, which are being used to enhance the use of AM as a production technology by making validation protocols more efficient.

03/12/2020

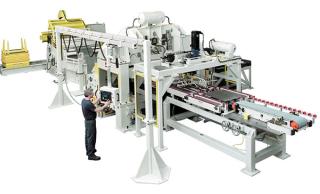

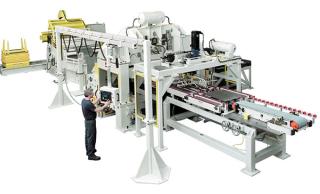

Burr Oak Tool Inc. is a leading producer of dies used to produce two types of fins for window air conditioners. Evaporator fins on the side of the air conditioner inside the window transfer heat from the inside air to the cold refrigerant flowing through the evaporator coil. Compressor fins located on the side of the air conditioner outside the window move heat from the now hot refrigerant to the outside air. Burr Oak Tool dies progressively stretch and reform the fins through a series of metal forming operations that extrude and reduce the thickness of the fins.

03/12/2020

Cresco, Pennsylvania-based Weiler Abrasives, a leading provider of abrasives, power brushes and maintenance products for surface conditioning, announced the promotion of John Hobbs to director, national accounts.

03/12/2020

The industrial control robotics systems perform, control and monitor a wide range of industrial operations and automated processes. The objective is to improve the overall quality, reliability and precision of these processes.

03/11/2020

I received an email from Lynn Fifer, a retired cutting tool professional and CTE reader since 1967, who shared his recollections about the development of the parabolic flute drill. Fifer said the development occurred in 1950s at the old Mohawk Tools Inc., Montpelier, Ohio, well before he started with the toolmaker in 1967.

03/11/2020

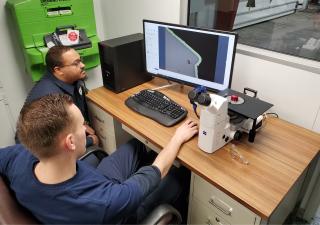

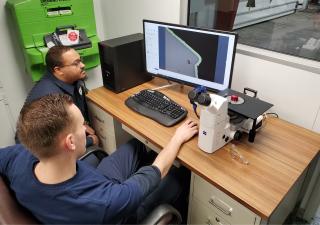

Hermitage, Pennsylvania-based Solar Atmospheres of Western PA (SAWPA) now offers in-house metallographic testing, with its purchase of a Zeiss AxioVert A1 Inverted Materials Microscope, with an accompanying Axiocam digital camera and Zen Core Materials Analysis software package. The investment represents the continued commitment by SAWPA to anticipate and meet customers’ needs.

03/11/2020

Precision Cutting Technologies Inc., Rockford, Illinois, has acquired Supermill LLC. Precision Cutting Technologies holds Alleghany Capital’s investments in the precision automated machine tool and high-performance cutting tool sectors. Headquartered in Berlin, Connecticut, Supermill is a leading manufacturer of high-performance carbide endmills.

03/10/2020

Wildeck, Waukesha, Wisconsin, announces the appointment of Dan Lorenz as its new president.

03/10/2020

U.S. Tsubaki is known for producing precision power transmission parts for some of the best-known OEMs in the automotive industry worldwide. The quest for quality craftsmanship and operating efficiency is standard procedure in Chicopee, Massachusetts, where the company’s Automotive LLC division operates a state-of-the-art manufacturing facility.

03/10/2020

United Grinding North America Inc., Miamisburg, Ohio, announced it has entered into a partnership with Dynamic Machine of Detroit, a Troy, Michigan-based CNC equipment dealership. For those United Grinding North America customers in the Michigan territory, the partnership will further strengthen grinding machine sales, service and application support.

03/10/2020

Vision Engineering, U.K. and U.S. designers and manufacturers of high-quality digital and optical visualization systems, opened a new technology collaboration and training facility in Irvine, California, just south of Los Angeles.

03/10/2020

Glebar Co., Ramsey, New Jersey, named Josh Wendrickx strategic account manager. He will cover the Midwestern U.S.

03/10/2020

Troy, Michigan-based Dallas Industries, a leading manufacturer of coil handling, press feeding equipment and controls for the stamping industry, has announced the appointment of William "Bill" Konieczny as engineering manager at its Troy facility. The announcement was made by CEO Willie Chacko.

03/09/2020

MC Machinery Systems Inc., Elk Grove Village, Illinois, has announced that Carlson Fabrication Solutions Inc. and Cimarron Industrial Sales are distributors for its laser and press brake machinery.

03/06/2020

The manufacturing sector is experiencing a major transition worldwide due to major advancements in technology. At present, as Industry 4.0 continues to make inroads across a range of manufacturing facilities worldwide, the digitization trend has set its foot into steel production– a factor that is positively impacting the long rolling space. The demand for cut-to-length line systems is witnessing significant growth, as steel producers continue to rope in significant efforts to fulfill the consumer demand for on-time delivery and product requirements while simultaneously running a lean operation.

03/05/2020

Wall Colmonoy celebrates its golden anniversary of 50 years of making metals work harder in Pontardawe, Wales. Wall Colmonoy, a family-owned and operated organization with facilities throughout the U.S. and U.K., is a global leader in materials engineering the aerospace, automotive, glass, oil and gas, mining, energy and other industrial sectors.

03/04/2020

March 4, 2020 – Mazak Corp. announced that it hosted NASA’s new administrator James Frederick “Jim” Bridenstine and Rep. Thomas Massie of Kentucky at its Florence, Kentucky, North American manufacturing headquarters. The administrator and congressman made a special trip to Mazak after attending a high-level round-table event with Mazak President Dan Janka, representatives of local aerospace manufacturers and educational leaders, and three Ohio state congressmen and other area politicians.