Industry News

07/28/2022

Advanced rotary surface grinders speed maintenance, extend tool life, and decrease press downtime compared to traditional, labor-intensive grinding methods.

07/27/2022

Ceratizit has named Scott P. Walrath as its head of business development for the Solid Round Tools division. Walrath brings 39 years of management, sales and product development experience to the position.

07/26/2022

Star Cutter Company is continuing its support of Alpena Community College’s manufacturing programs through increased monetary and equipment donations to the college. The donations will be supplied over a two-year period of time, helping to bring state-of-the art manufacturing equipment, such as grinding machines and optical comparators, to the center for hands-on training opportunities.

07/25/2022

Mastercam sponsored competition encourages innovative design and manufacturing.

07/22/2022

Figuring out how to meet rising production demand can be deceptive. On the surface, it’s a simple math problem. If you have one machine on the floor and it makes eight parts per day, and you need to produce 16 parts per day, just add another machine, right?

07/22/2022

Rachid M'Saoubi’s role within Seco Tools as senior research and development expert might sound complex, but for him, it’s about building bridges between the academic world and the needs of Seco Tools and its customers to help them stay competitive and thrive.

07/21/2022

Mazak Human Resources Director William Weier has accepted appointments to two Northern Kentucky advisory boards that guide regional employment policies and align education to employer needs.

07/20/2022

Ceratizit USA, manufacturer of standard and custom tooling for the metalworking industry, has announced staff additions in the East, South and Midwest territories.

07/19/2022

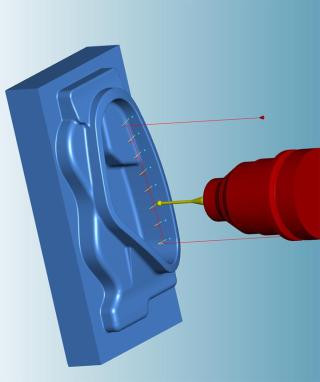

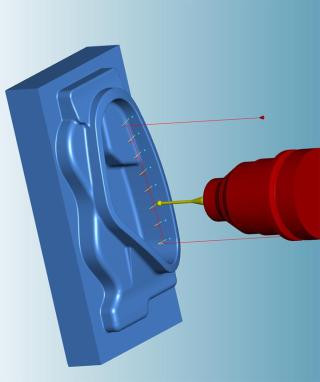

Emuge-Franken USA, Grob Systems Inc. and Open Mind Technologies are jointly holding a complimentary mold and die workshop July 20 from 10 a.m. to 1 p.m. ET at the Emuge Technology Center in West Boylston, Mass.

07/18/2022

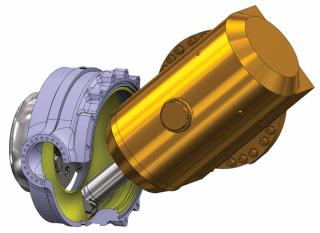

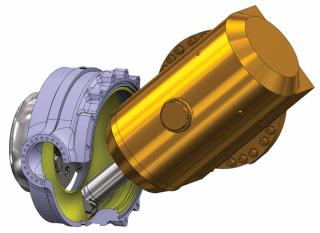

Orthopedic hip surgery numbers are forecast to increase at a rate of 5% year-to-year until 2026, and with this trend, an increased demand for tools and components to support these procedures will emerge.

07/15/2022

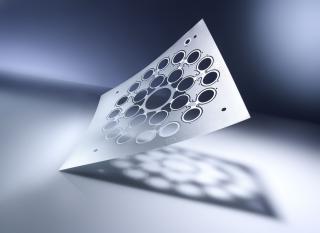

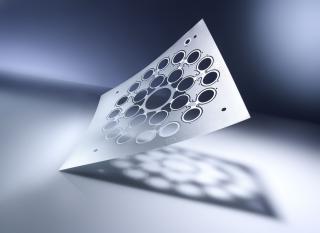

Leading European photochemical etching specialist micrometal GmbH (incorporating HP Etch and Etchform) has perfected using the PCE process for the production of ultraprecise metal parts and components.

07/14/2022

The paper serves as a guide to improving safety, speed and efficiency on cutting and burn tables.

07/13/2022

Vecoplan supplies outstanding machine and plant technology for the economical processing of residual materials and waste for the purposes of material and thermal recycling. A new turning machine has cut machining time in half.

07/12/2022

Long before a new car model hits the streets, you could already touch it at MT Technologies -– if everything were not so top secret. The model maker manufactures entire vehicles as a reference and test models made of aluminum for numerous OEMs.

07/11/2022

SW North America's demonstrations will include live machining of a battery housing for a hybrid automotive vehicle on the BA W08-12 and a gun slide on the BA 322i.

07/08/2022

More than 3,000 Hexagon AB customers, partners and colleagues, as well as members of the media, attended the Stockholm, Sweden-headquartered company’s HxGN LIVE Global 2022 conference at The Venetian Convention & Expo Center in Las Vegas June 20-23.

07/07/2022

Industry input drives multiaxis, mill-turn advancements.

07/06/2022

Mazak Canada hosted machine technology and AI events in Edmonton and Cambridge.

07/05/2022

Rollomatic Inc. in Mundelein, Ill., has appointed Brian Twohey as national sales manager for the United States and Canada. He will also join the Group Management Team at Rollomatic/Strausak North America.

06/29/2022

In an industry moving at lightning speed, ANCA Tool of the Year (TOTY) celebrates the deep experience and creativity of the craftspeople who create the next generation of cutting tools.