Industry News

06/28/2021

International kitchen cabinet hardware manufacturer uses CGTech’s VERICUT to train machining apprentices.

06/27/2021

Goellner and its subsidiaries bring an extensive product portfolio to the network.

06/25/2021

Transor Filter is celebrating its 10-year anniversary of conducting business in Brazil. A decade ago, the company introduced its edge filtering concept to Brazil, which afforded companies that produce products such as carbide cutting tools an opportunity to be more competitive in a global market.

06/23/2021

CNC Software Inc., developer of Mastercam CAD/CAM software, has become a member of the Oregon Manufacturing Innovation Center Research and Development (OMIC R&D).

06/23/2021

New opportunities are expected with the new investment in the company.

06/21/2021

At the 2021 Precision Machining Technology Show (PMTS) scheduled for Aug. 10 to 12 in Cleveland, Mazak will highlight some of its latest high-output, cost-effective and space-saving machine tool technology.

06/21/2021

Many countries are moving to end the sales of fossil-fueled cars, and auto manufacturers are experimenting with electric vehicle technology to meet these requirements. The trend may have an impact on cutting tool sales, according to a new post by ANCA, a manufacturer of cutting tools.

06/18/2021

GWS Tool Group has named Michael Keener as an application specialist who is responsible for supporting GWS distributors and key metalworking customers in the application of GWS high-performance cutting tool solutions

06/17/2021

Open Mind Technologies USA Inc., the North American subsidiary of Open Mind Technologies AG, is celebrating its 25th anniversary of CAM software achievements.

06/16/2021

The Ceratizit Group is hosting a global online event, “It’s Tool Time,” on June 17 to focus on the value of process optimization through a variety of interactive machining demonstrations and presentations.

06/15/2021

For the Austria-based Wittmann Battenfeld company, it's all about plastic. The company utilizes a modern, diverse and modular range of machines for processing plastics and other plasticisable materials, including the M30 Millturn from WFL Millturn Technologies.

06/14/2021

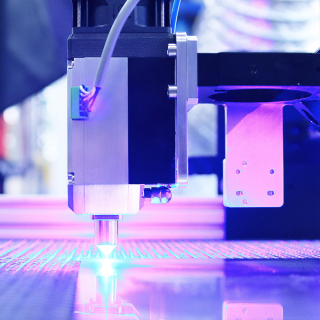

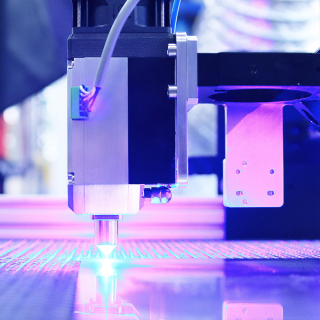

Global trends toward reducing carbon footprint and operational costs as well as the push for high-precision processing tools have led to increasing demand for compact laser systems that can be implemented in processing plants and production lines.

06/14/2021

During a vacuum processing cycle various chemical reactions can occur in a vacuum furnace that can cause a “metallurgical meltdown,” according to the authors of a new paper on the subject.

06/11/2021

Auto parts manufacturer SB Dezigns in North East, Maryland, has implemented a new end mill and chuck solution that helped them save 62% in costs on a recent application.

06/10/2021

Contract manufacturers across the country provide technical capabilities for customers who do not have to invest in machinery or labor. Some of these versatile manufacturers have added advanced additive technologies to their arsenal.

06/09/2021

Hundreds of U.S. manufacturing companies ask President Biden to terminate Section 232 steel and aluminum tariffs.

06/07/2021

Star Cutter Co. has upgraded its facility that produces tool and broach grinders. Upgrades to the 25,000-sq.-ft. climate-controlled building include a 1,500 sq. ft. area for customer run-offs and demonstrations with space for two machines at any time.

06/06/2021

Many TNC functions of Heidenhain controls offer possible solutions to the conflicting demands of a production process that is simultaneously precise and efficient. Here is a look at some of those functions.

06/03/2021

Edmund Boland takes the role of General Manager Europe; Martin Winterstein, who is an external appointment, was named Sales Manager Europe, and Jan Langfelder moves to Global Key Accounts Manager.

06/03/2021

GWS Tool Group named Jack Crawford as an application specialist.