Industry News

11/19/2018

Continuous learning, continuous improvement, continuous generation of ideas—they’re all important things. I would like to think they’re especially important to manufacturers but am struggling to come up with a specific reason. Every business, from floral arrangers to drywallers, must continually adapt and evolve or face eventual corporate death. Perhaps the reason continuous learning and improvement are so relevant to manufacturing, which in this context means machining, is that our industry is one of the fastest changing in terms of technology.

11/16/2018

Depending on whom you ask, you’ll receive wildly different unravelings of the acronym DFAM. To music aficionados, DFAM might mean “drummer from another mother,” clever branding from Moog Music Inc. to describe its newest line of percussion synthesizers. I wish I’d thought of that phrase. DFAM could mean the Darlington Farmers Auction Mart but probably only to those who live near there in England and are interested in buying a cow, goat or sheep. At The Walt Disney Co., DFAM refers to the extended family of employees who share the stress of working at the Magic Kingdom—as in, “I’m going to chill this weekend with my DFAM before the big Labor Day rush.” Then there’s the DFAM that manufacturers care about—or rather the additive manufacturers. That’s because DFAM is short for “design for additive manufacturing,” an acronym every bit as relevant to machinists as it is to people in 3D printing.

11/15/2018

A fact sheet by the National Immigration Forum focuses on immigrants in the U.S. manufacturing sector, highlighting key information about their demographics, incomes and contributions.

11/15/2018

Modern manufacturing is a diverse, inclusive community, embracing and supporting the creativity that each person can bring to build something bigger than an individual. Many manufacturers are setting great examples of what the future of the workplace will look like and of what other firms should aspire to achieve. Learn the five key themes that manufacturing companies are addressing to take their diversity and inclusion work to the next level.

11/15/2018

The future development impetus of the internal combustion engine will focus on the reduction of emissions. This is dependent on fuel consumption, which in turn is determined by the internal engine friction. The goal of form honing is a form optimized cylinder bore under operating conditions.

11/15/2018

Exclusive watches - “made in Australia?” Absolutely, thanks to Nicholas Hacko, a talented watchmaker who opened a small factory making high-quality timepieces in Sydney a few years ago. To be flexible and competitive, he invested in a high-precision 5-axis machining center from Kern Microtechnik, enabling him to reliably produce the micron-accurate parts, which are the basis for his business today.

11/15/2018

Equipment manufacturers, engineering, procurement and construction (EPC) companies, and power and process plant owners and operators commonly face the challenge of keeping their fleet, machinery, and other assets working efficiently, while also reducing the cost of maintenance and time-sensitive repairs. Considering the aggressive time-to-market required for industrial products and services, it is crucial to identify the cause of potential faults or failures before they have an opportunity to occur. Emerging technologies like the Internet of Things, big data analytics and cloud data storage are enabling more vehicles, industrial equipment and assembly robots to send condition-based data to a centralized server, making fault detection easier, more practical and more direct.

11/14/2018

Olis Robotics, a leader in next-generation remote robotics software, announced its selection as a subcontractor by Tethers Unlimited as part of the NASA FabLab prototype project. The FabLab will be used on missions aboard the International Space Station (ISS) to demonstrate orbital recycling and reuse capabilities by providing on-demand manufacturing of mission-critical parts. It’s a first step toward on-demand orbital manufacturing through reclamation, recycling and 3D metal and plastics printing.

11/13/2018

After being at AB Sandvik Coromant, Sandviken, Sweden, for 17 years, Nadine Crauwels was appointed global president of the cutting tool manufacturer in May 2017. She has had roles in sales, product management, product introduction, custom tools and strategic relations.

11/12/2018

We are in part three of our article series “Poly–poly–or what?” The series looks back at the time between autumn 1974 and the Hanover Trade Show in the spring of 1975. Dealing with this new cutting material “polycrystalline diamonds” (PCD) was fascinating for all of us; after the presentation at the first Hanover Trade Show in 1973, each day brought new insights for production and for different applications.

11/12/2018

Fraisa SA is a family-owned business that offers its customers a complete range of endmills, drills and taps. The toolmaker provides a full customer service offering with logistics, specials, regrinding and recycling of tools. With its headquarters in Bellach, Switzerland, Fraisa has a strong position in Europe and entered the U.S. and Chinese markets in the last 10 years.

11/08/2018

Researchers at the University of Waterloo have taken a huge step towards making smart devices that do not use batteries or require charging.

11/07/2018

Many parents undervalue manufacturing as a career for their children. However, when parents were told about the financial benefits of jobs in manufacturing, they said they would encourage their children to explore the field.

11/07/2018

Caterpillar Inc.'s E4Life program partners with public schools in Peoria, Illinois, to provide hands-on manufacturing experience to high school students with a focus on innovation. Prior to the implementation of this program, Caterpillar spent time with students and potential participants to find out what barriers stand between them and the workforce.

11/06/2018

Cluster’s CEO and founder, Kim Taylor, has been highlighted in People Magazine’s feature "25 Women Changing the World."

11/06/2018

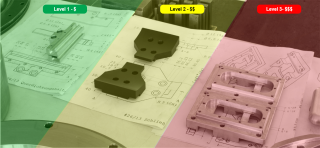

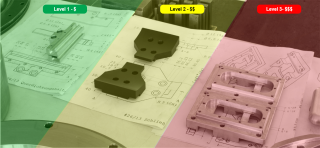

A shop’s product mix, the types of jobs running in the shop, can make or break it. The right mix increases profitability and makes for happy customers. The wrong mix risks demoralizing the shop and upsetting customers, ultimately resulting in more stress and less profit. Actively managing your product mix to correctly fit your shop makes life much easier. However, it does take intention to step away from the jobs you know your shop can, but shouldn’t make.

11/05/2018

ROCKFORD, IL, OCTOBER 18, 2018 -- To accommodate rapid growth and future expansion, Rockford Systems, LLC., a provider of machine safeguarding products, safety education and industrial safety services, is pleased to announce it is moving its headquarters into a new, larger facility located at 5795 Logistics Parkway in Rockford, IL.

11/05/2018

TROY, Mich., October 11, 2018 – Seco Tools has named Tyler Martin as its new manager of engineering services.

11/05/2018

Richfield, WI – – – Jim White, National Sales Manager of Carmex USA, has announced the opening of a new distribution center to serve the expanding West Coast market.

11/05/2018

Waukesha, WI – Wildeck, Inc. is pleased to announce and welcome Daniel Lorenz as the new Vice President of Operations.