Heller Machine Tools offers a technology for coating cylinder bore surfaces of lightweight automotive aluminum engine crankcases, imparting a durable material, extending engine life, and enhancing performance.

To date, lightweight motorblocks use cylinder liners, but there is now a practical alternative in twin-wire arc spraying, an extremely cost-effective technology for coating cylinder bores. Partnering with Daimler AG and other partners, Gebr. Heller Maschinenfabrik GmbH is tasked with industrializing all the steps of the process and developing the technology into a reliable process. It will be marketed globally under the name of Heller CBC (CylinderBoreCoating.) Heller will also integrate the process into volume engine production.

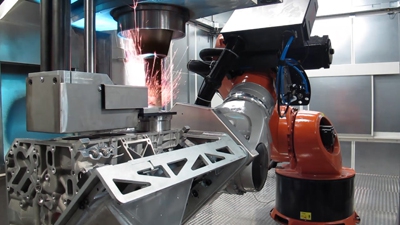

The twin-wire arc spraying process continuously melts iron/carbon wires and sprays them onto the cylinder bore surfaces of the lightweight aluminum crankcase with the help of a nitrogen gas flow.

Compared to other thermal coating processes, the technology is considered extremely cost-effective and technologically superior--a reliable, repeatable, highly controllable economical process that vastly improves the cylinder bore surfaces, reducing wear and promoting long-life. Spray particle velocity 60-80 m/s and spray particle temperature up to 2,000 degrees C.

Besides the primary coating process, the CBC machining process at Heller includes fine boring, roughening, finish honing to expose pores, and finish machining, all accomplished in a complete manufacturing system consisting of the innovative coating module, Heller CBC 200, and the Heller MC20 machining modules. Total cycle time, including part load/unload, for an 8-cylnder engine 5 to 6 minutes. The engine blocks may be direct-loaded into the machining module or mounted on a swiveling exchanger.

"Although the technology has only been used for exclusive low-volume series until now, its application in medium-volume production already provides significant competitive advantages compared to existing cylinder lining technologies," said Vincent Trampus, Heller Vice President of Sales. "The technology complies with the production rules and criteria of the automotive industry. Now, it is only a small step to mass production."

Contact Details

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.