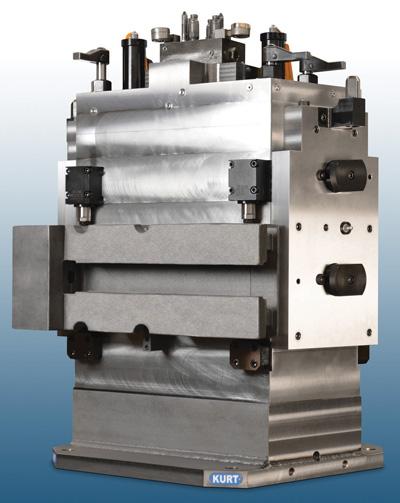

New machining projects and ones requiring improved throughput can benefit from a custom engineered workholding system from Kurt Manufacturing Co. The benefits reportedly include: high precision and repeatable part clamping, high density, flexible clamping of a family of parts on the same fixture, high rigidity and automated high productivity/output.

By maximizing the productive capacity of machining centers, a Kurt custom engineered workholding system will increase part output while lowering costs. This is accomplished with high-density workholding designs and fast load/unload features. Kurt offers a range of standard products. By first analyzing the possible use of its standard vise products, Kurt ensures the overall lowest workholding cost. By utilizing standard products in conjunction with custom modifications, upfront costs and future maintenance can be greatly reduced. Kurt controls the manufacturing of both the standard product and custom fixture ensuring the new workholding setup is matched dimensionally.

Kurt offers high precision, high quality standard product solutions. From tombstones, to manual vises, to dedicated hydraulic vises, to a completely new design, Kurt has the solution. Kurt's custom workholding engineers have built an industry leading reputation assisting automotive, aerospace and other metalworking intensive industries to improve quality and reduce cycle times. Kurt's custom engineered workholding includes options for hydraulics, air sensing, prox switches and part gaging to accommodate various part sizes within a family of parts. Kurt's in-house workholding design engineers are experienced in integrating workholding into automated cells.

By integrating robot arms into fixtures, productivity can be greatly increased allowing automated part loading, machining on all sides of parts and unloading and stacking of finished machined parts. Systems also can include automated part gaging for quality and real time process control with complete part traceability. These custom systems can be designed for a single machining center or to automate an entire cell of dozens of machining centers and support systems.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- family of parts

family of parts

Parts grouped by shape and size for efficient manufacturing.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- process control

process control

Method of monitoring a process. Relates to electronic hardware and instrumentation used in automated process control. See in-process gaging, inspection; SPC, statistical process control.