Perceptron Inc. has developed a green laser scanner for coordinate measuring machines that works with aluminum and carbon-fiber-composite parts. In the past, integrating 3D scanning software on a CMM or portable CMM was expensive and awkward, according to Song Chung, senior vice president and CTO at Perceptron.

“With 3D printing and reverse engineering advancing so rapidly, we saw a void in the market for a laser scanning solution,” he said.

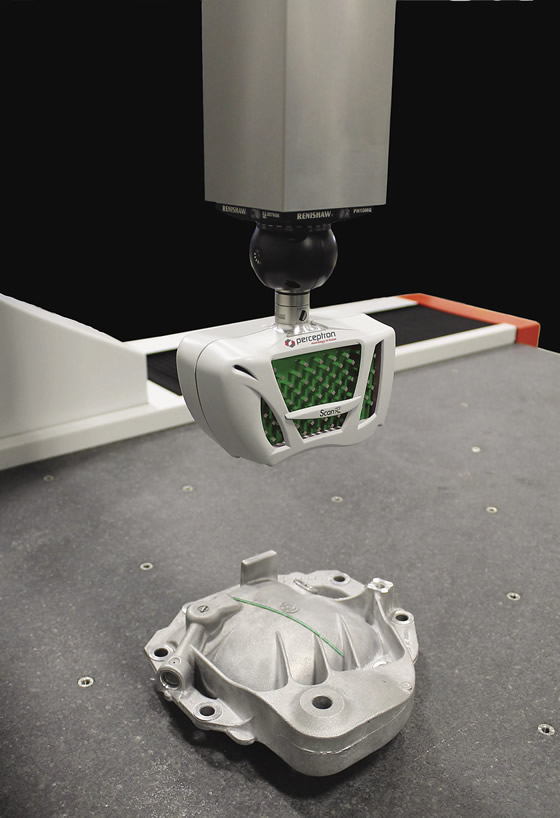

The ScanR, which is Perceptron’s sixth-generation laser scanner, provides a wider spectrum within the dynamic range than red or blue lasers and without the reflective noise. This results in a laser scanner that offers improved material coverage, edge detection and accuracy, as well as a better signal-to-noise ratio.

The ScanR universal CMM green laser scanner from Perceptron offers improved material coverage, edge detection and accuracy, as well as a better signal-to-noise ratio. Image courtesy Perceptron.

Chung said the use of green laser was once considered expensive because the wavelength was difficult to achieve. Instead of a single process, it took several additional steps, more optics, more space and more energy to produce. “New technology, however, has solved many of these issues in terms of stability and affordability,” he said. “In our development process, we were able to apply the right set of optics to make good use of the green laser spectrum, optimizing the wavelength over that of red or blue lasers.” (Green lasers have wavelengths from 490nm to 560nm, red lasers from 630nm to 700nm and blue lasers from 360nm to 480nm).

One advantage of using a green laser compared to a red one on a highly reflective carbon-fiber part is end users don’t have to spray the part with a powder coating. “Carbon-fiber surfaces have a clear coating over the fiber texture,” Chung said. “Red lasers will look right through the coating and see the actual fibers, while green and blue lasers will reflect off the clear surface, providing good surface detection.”

Another advantage with ScanR is the adjustable data-acquisition rate for high-quality and high-speed operation. This largely depends on the application, part size and shape complexity. “If it’s a small part with a high geometry, you want to slow down acquisition but try to get more resolution,” Chung said. “With large areas like a door or fender, part variation is not too high, so you want a higher speed to reduce data-acquisition time and eliminate unnecessary data that you may ultimately throw away.”

ScanR can be integrated into Perceptron’s TouchDMIS metrology software, which offers a one-touch scanning interface and allows initial user setup via a tactile measuring probe, according to the company. Feature extraction from the generated point cloud allows automatic inspection of part features against nominal feature definitions from CAD.

This laser scanning concept complements 3D printing whenever there is a need to create modify or adjust a digital copy of a critical part—for example, when you have just one original part and want to make it in varying sizes. “Also, you may want to use the scan to compare it with the original part data in order to verify and/or inspect the 3D-printed part,” Chung said.

For more information about Perceptron Inc., Plymouth, Mich., call (734) 414-6100 or visit www.percep tron.com.

About the Author: Matt Jaster is senior editor of CTE. Contact him at (847) 714-0174 or [email protected].

Related Glossary Terms

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).