I’m spoiled. With few exceptions, I machine everything I can on CNC machines. In most cases, jobs are less labor-intensive, less prone to error and are completed faster than when using manual, or conventional, machines. With the user-friendly CNC technology available today, even making one or two simple parts is often easier and more efficient.

This doesn’t mean the end of manual machining is near. There are certain tasks you can do with conventional machines that CNC machines are just not good at, such as “blending.” CNC machines can’t blend flawed features very well, simply because they don’t have “eyes.” They run on numbers. Many jobs that come through the door don’t have any documentation, any exact numbers to work toward.

Often parts than need rework are so beat up, worn out or outdated that, even if you had a print, there’s a good chance the dimensions on the print won’t match the part. Maintenance machining and mold repair come to mind as jobs that often need manual blending of some sort.

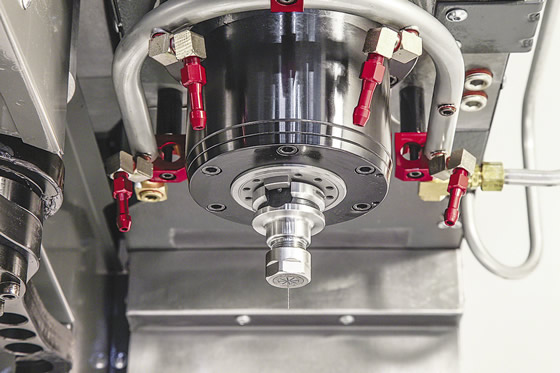

The planning and cutting characteristics of manual and CNC machining are quite similar, with the exception that you can machine parts a lot faster on a CNC machine, such as this Haas DT-1 drill/tap center. Image courtesy Haas Automation.

There are craftsmen in our shop who know little about CNC machining and CNC machinists who are not craftsmen. The funny thing is that often these people imagine the other as having some kind of supernatural abilities. The fact is little would get accomplished if it weren’t for these two groups working together.

CNC machining involves a combination of machining knowledge, controller familiarity and programming expertise.

Machining is the art of removing material in the proper sequence, selecting and sharpening cutters, setting speeds and feeds, measuring and determining how to hold the work. The planning and cutting characteristics of manual and CNC machining are quite similar with the exception that you can machine parts a lot faster on CNC machines, because they can read numbers quickly and move accordingly. They also don’t take coffee breaks.

CNC programming, at its core, is simply point-to-point programming, which, in turn, obliges the cutter to move from point to point. You don’t have to be especially adept at doing mental gymnastics to program CNC machines, because almost all the instructions you give the machine are sequential. It’s a lot like driving: “Go north 3 miles and turn left.”

The practice of starting to learn on conventional machines may be shifting as CNC machines become increasingly more popular, less expensive and easier to use. If you are an experienced manual machinist, you’ll have the advantage of being able to concentrate your efforts on learning the controller and how to program. It isn’t essential to have experience on manual machines to learn CNC machining, but someone with a strong, manual machining background will likely have an easier time getting good parts consistently.

To the untrained eye, CNC machines may look complicated. They did to me at first, and I couldn’t imagine how anybody could machine parts simply by pressing buttons on a control panel.

When I signed up for a CNC programming course years ago, I asked the instructor how long he thought the average person would need to set up and operate a CNC machine. His answer—“a couple of days”—surprised me. In my ignorance, I figured it would take at least a couple months of intense training, but the instructor was correct.

The other day while running a job on a CNC mill, I took some time to look over the list of G codes posted on the control. To my surprise, I wasn’t familiar with a lot of them. I have literally programmed and run thousands of different parts through these machines. “How can that be?” I asked myself. The only logical conclusion was you don’t have to know “everything there is to know” to make parts on these machines.

What I strive for and demand of myself is being able to accomplish whatever machining job comes through the door. If I don’t know some aspect of doing a job, such as thread milling, I’ll learn it.

I have always preferred learning something new by doing a project. That way I immediately start to separate what is important from what is not.

The CNC machines and controllers I’ll discuss in this column are primarily from Haas Automation Inc., because that is what we use in our shop. Although the setup and programming procedures are specifically for Haas machines, they will likely be useful in a generic sense for CNC machines from other builders.

About the Author: James A. Harvey is a machinist and plastic moldmaker who has worked in shops across the U.S. for nearly 40 years. Harvey’s column is adapted from information in his book “CNC Trade Secrets: A Guide to CNC Machine Shop Practices,” published by Industrial Press Inc., South Norwalk, Conn. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE20OFF when ordering, CTE readers will receive a 20 percent discount off the book’s list price of $29.95.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.