When I began machining, CNCs were just coming into mainstream use. The first shops I worked in had only conventional (manual) machines. It wasn’t until the mid-1980s that I started to notice the incredible versatility of CNC machines. The complex contours and shapes the machines could generate made many jobs much easier. The use of templates to file and sweep in surfaces was rapidly becoming a thing of the past.

Initially, I was intimidated by the technology. The mysterious code that ran the machines seemed to be the domain of computer experts; it was seemingly beyond my comprehension. It wasn’t until I took a class in programming that the mysteries started to dissolve.

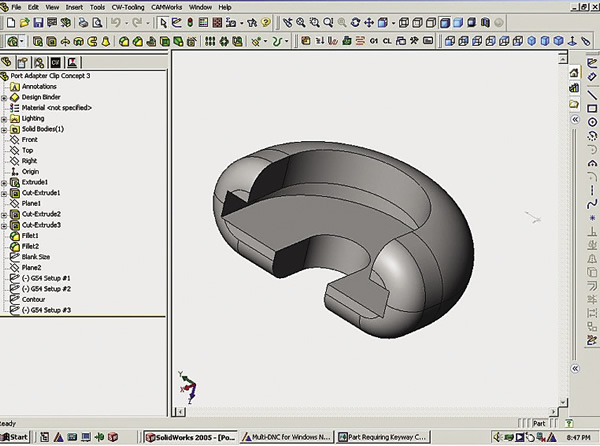

Parts are often easier to model than they are to machine. All images courtesy J. Harvey.

As versatile as CNC machines are, they are only as good as the people programming and operating them. The cliché “garbage in, garbage out” is well-suited to CNC programming and machining. There is simply no substitute for proper planning and machining know-how. In addition, a programmer without much machining experience would likely struggle to consistently produce good parts.

One of the great virtues of CNC machines is that, while they are running, machinists can work on other tasks. In essence, CNC machines take the labor out of machining.

Another virtue of CNC machines is that the cut-and-measure processes so prevalent in conventional machining are virtually eliminated. If programmed and set up correctly, the cutting tool will go precisely where it should so that dimensional accuracy comes quickly. Usually, only minor adjustments are needed to compensate for slight variations in tool size.

For anybody who wants to learn the machining trade, gaining experience on manual machines has advantages, but it’s not entirely necessary. For example, I taught an inexperienced industrial engineer how to use our CAD/CAM software and CNC machines. Once he became familiar with the software and the different speeds and feeds suitable for various cutters and workpiece materials, he became an asset to our shop.

It’s important to initiate a new project with proper planning. It is one thing to create a beautiful model or drawing on a computer. It is quite another to figure out how to hold the part for machining.

Planning involves a variety of decisions before any material is cut. The list of questions to answer includes:

- How is the part going to be held? Will a fixture be needed?

- What sequence of setups will be used?

- What size raw stock are you going to start with?

- What size cutters will you choose and are they available?

- Will squaring be done beforehand or in the part program?

- Is the part rigid or will flimsiness be an issue?

- What speeds, feeds and DOC will you choose?

- Where are the G54 starting points going to be placed?

- Will the part have to be roughed first before finishing to avoid warpage?

Because of the infinite variety of machined parts, especially milled parts, it is somewhat difficult to categorize how to go about planning. There are enough similarities, however, that certain techniques can be successfully used time and again.

One paradox that machinists face is if a job runs smoothly, nobody pays much attention. Therefore, any time you planned and executed a job that runs smoothly, give yourself credit.

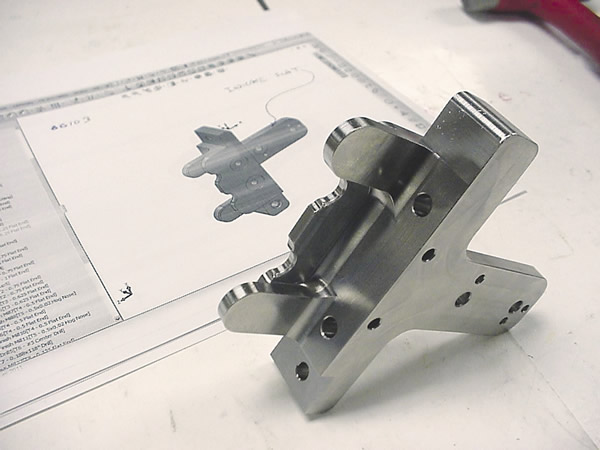

Some parts can be planning nightmares.

As a beginner, there will be no shortage of people willing to offer advice about what they think is the best way to run a job. It’s tough being a beginner. There are countless ways one could run a job, and many have no advantage over another. If a job runs smoothly, parts will be in tolerance and work will be completed in a reasonable amount of time—and you will have accomplished your mission.

With that being said, it is always humbling when you think you’ve planned a job well and it turns into a nightmare. I believe planning, programming and selecting the machining parameters before cutting anything are basically educated guesses. Therefore, the more experience you gain, the better your guesses become.

About the Author: James A. Harvey is a machinist and plastic moldmaker who has worked in shops across the U.S. for nearly 40 years. Harvey’s column is adapted from information in his book “CNC Trade Secrets: A Guide to CNC Machine Shop Practices,” published by Industrial Press Inc., South Norwalk, Conn. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE20OFF when ordering, CTE readers will receive a 20 percent discount off the book’s list price of $29.95.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.