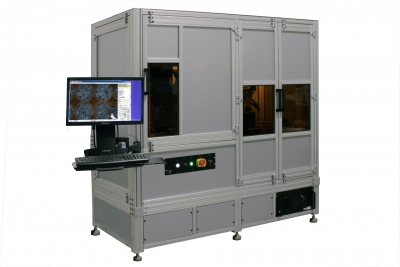

PhotoMachining Inc. recently installed its new MicroMachine – USP III utrashort pulse laser micromachining workstation at a world renowned medical care and research institution for the development of novel medical, implantable, surgical and diagnostic devices.

According to Dr. Ronald Schaeffer, president and CTO of PhotoMachining, “The MicroMachine –USP III provides the ultimate flexibility in ultrashort pulse or ultrafast micromachining. The workstation uses a powerful 20 watt femtosecond laser with three wavelengths: infrared, green and ultraviolet. Additionally, the pulse duration is adjustable from 290 fs to 10 ps.” This gives the engineer an unprecedented capability to fully explore the effects of wavelength and pulse duration on a given material. The high peak power of the laser permits virtually any material to be micromachined with exceptional quality and resolution, according to the company.

The sophisticated beam delivery includes two galvo scanning heads, one for infrared and green and the second dedicated for ultraviolet. An optional spindle stage can also be integrated into the system for the manufacture of stents, catheters and other tubular components. PhotoMachining’s LaserSoft program coordinates everything from wavelength selection, stage movement and optical inspection.

Although designed for advanced medical device manufacturing, the system has broad appeal for any industry researching ways of using lasers in micromanufacturing. Once the laser processing parameters are determined, this industrial hardened system can migrate directly into a production environment.