Optomec, Albuquerque, NM, a global supplier of production-grade additive manufacturing systems for 3D printed metals, launched a new tool series today at IMTS 2016 that reportedly enables low-cost, high-value metal additive manufacturing.

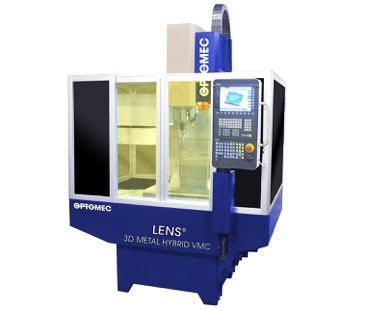

The new LENS Machine Tool Series integrates Optomec’s LENS metal additive manufacturing technology into conventional CNC vertical milling platforms, which results in breakthrough price points as well as the industry’s first Hybrid VMC Controlled-Atmosphere System, according to the company.

Optomec also announced an agreement with Fryer Machine Systems, a producer of high-quality, affordable machine tools, to integrate the Optomec LENS metal additive manufacturing solution into Fryer's new LaserFab 3D hybrid machining centers. Pricing for Fryer’s hybrid VMCs (Vertical Machining Centers) will start under $350,000.

Fryer will demonstrate their new hybrid LaserFab series at IMTS in the South Hall (Booth # S8719). Optomec will be in the North Hall (Booth # N73).

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.