Especially within the aerospace, energy and mechanical engineering sector, production managers have to bridge the gap between economic efficiency and high process reliability when working with materials that are difficult to machine. Fortunately, there is peace of mind in knowing that the machine technology innovations continue to develop to meet the ongoing demands of manufacturing.

Heller machine tools is known as a source of inspiration for these kinds of innovations. The company, located in Nuertingen, Germany, is known for its high-quality 4- and 5-axis CNC machining centres, CNC mill/turning centers, CNC machines for crankshaft and camshaft machining, as well as flexible manufacturing systems. Customers value its availability of products and its competency in managing special processing demands. Both qualities stem from Heller’s in-house manufacturing, which relies on closer collaboration with customers, suppliers and research institutes to remain on the forefront of innovation.

Werner Kirsten, who is working in the Technology Development Department at Heller and is responsible for the area of "difficult-to-machine materials“, explains: "Our service includes optimizing the machining processes together with our customers and suppliers. To support such services with practical trials, our Technology Center is equipped with a variety of machines."

In most cases, the aim is to increase the productivity without compromising the process reliability. Technologist Kirsten adds, "We often achieve this aim with an optimized roughing operation which ultimately results in a reduced finishing process. By maintaining the same technological values, but shortening the finishing depth of cut by 50 percent, the overall machining time is reduced to half. However, this requires process reliable and controllable systems during roughing."

In this regard, all machining components in the process chain have to be considered in order to improve productivity. The machine tool is the most evident component of the machining process, however the tool, the toolholding system, the coolant supply and other elements are also essential for a successful operation.

"In the end the weakest link of the process chain limits the success," Kirsten emphasizes. In his opinion most machine shops don't pay attention to the toolholder even though it is especially significant for high-performance cutting. "Many of the trials which we carried out during the last few years have proven this

point," Kirsten explains. "We realized that the tool holder hasan incredible influence on the machining

process. In the case of reinforced shrink fit chucks, for example, the vibration node is closer to the bearing

point (due to the larger mass). The result is a smoother machining process with less vibration and a better

surface finish quality while using the same tool, machine, process parameters and fixturing technology."

By selecting the right toolholder, you can even achieve good productivity and surface quality results using

basic standard cutting tools. Kirsten refers to comparative tests with basic four-edge cutting tools without an inner coolant supply. As an alternative to a standard shrink fit chuck he selected a HAIMER Power Shrink Chuck with Cool Flash which ensures that the coolant is transported directly to the cutting edges. "Compared to using a normal shrink fit chuck and externalcoolant, we were able to achieve significantly better results."

When a group of representatives from the aerospace industry, the Technical University of Dortmund and Technical University of Hamburg-Harburg visited Heller,an especially extensivemilling application study was conducted in titanium Ti-6AI-4V.

The available machining center was a 4-axis Heller H 5000 with a gear unit and HSK-A100 spindle, which yields torques up to 2.290 Nm. In order to demonstrate the machining potential, different 25mm diameter endmills were used to mill full slots into a titanium plate. To simulate holder conditions used in the aerospace industry, the tools were clamped into reinforced shrink fit chucks. At an axial cutting depth of 0.5 to 1.0 x D the machining process was found to be very reliable. Since the spindle was not running at full capacity, the trial participants agreed to increase full slotting depth to 2 x D.

Kirsten explains: "Under these conditions the tool pulled out of the shrink fit chuck during the machining operation, creating a slot closer to 2.5 x D as it progressed through the part. Towards the end of the slot the tool finally broke as a result of increased cutting forces."

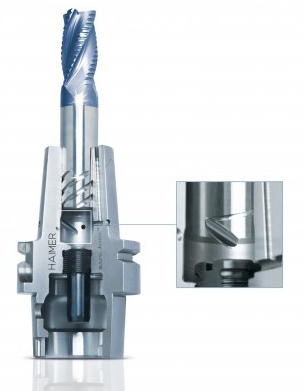

The milling specialists all agreed that the clamping force of the chuck was the limiting factor in this process. As soon as the axial pressure and process related vibrations are too high the tool moves out of the chuck and further into the workpiece. At the same time the cutting pressure increases such thatin the end the tool breaks and the workpiece is irreversibly damaged. Reasons and possible countermeasures were discussed intensively. In the end, Kirsten developed the idea that the tools are forced to navigate towards the spindle when the holding forces are exceeded. This is how he ultimately noticed the patented HAIMER Safe-Lock system, which in addition to frictional clamping forces, has the same helix pattern as the tool. Theoretically, he realized that even if the tool got loose while using Safe Lock, it would be pulled into the holder through the helical drive keys and not into the part. A movement that can be easily prevented through the use of length presetting screws.

Kirsten got in contact with HAIMER, the European market leader for tool holding technology, to test the Safe-Lock system: "We wanted to know if our ideas could be put into practice using the HAIMER system in an even less forgiving environment." The Heller technology developer repeated the described trial, with a few major changes. HAIMER Safe-Lock grooves were subsequently added on similar solid-carbide tools, but the application would be run again with a reduced spindle taper interface (HSK 63 instead of HSK 100), with a less rigid 5-axis gear driven spindle and a less stable diagonally fixtured workpiece.

The result: Despite these additional limiting factors, the tool was able to process a full slot of 2 x D = 50mm with complete process reliability. Kirsten says: "this way we were able to indirectly prove that Safe-Lock works and that the shrinking technology has even more potential with HSK-A100, especially on 5-axis machining centers with gear spindles."

Afterwards this samplemachining on Ti-6AI-4V was carried out various times, including during the Airshow in Farnborough, whereby it was proven that the previous limit of 1 x D = 25 mm full slotting in titanium could be doubled with the use of Safe-Lock.

Kirsten summarizes the results as follows: "For roughing operations this is a reliable process. Therefore, I consider the HAIMER Safe-Lock system a practical, easy-to-handle and process reliable addition to the shrinking technology, which we already utilize, especially in connection with standardized tools of other manufactures."

From the onset of its creation, HAIMER recognized the incredible potential of the Safe-Lock system, which is why the company created a licensing program to give innovative tool manufacturers the ability to integrate the patented pull-out protection system into their tools. The result of their vision to create a more open system has been a tremendous success, with 14 leading cutting tool manufacturers having signed licensing agreements, including Walter, Widia, Sandvik Coromant, Seco Tools, Sumitomo, Kennametal, Helical, Emuge Franken, Data Flute, Niagara, OSG, Melin, SGS Tools and Mapal.

Through the steady increase of Safe-Lock tooling in the market via Haimer and its licensed partners, the system has become a standard for heavy machining and roughing. The popularity and simplicity of Safe-Lock is such that it is also replacing the old Weldon clamping system, particularly when new milling strategies such as trochoidal (dynamic) milling are involved.

President of HAIMER Group Andreas Haimer explains: "With our Safe-Lock system we found a solution that combines a high runout accuracy with 100 percent pullout protection. The system has established itself successfully as a standard in the aerospace industry and, generally speaking, for roughing and heavy-duty machining. And now more and more companies that make use of the trochoidal (dynamic) milling strategy are also making the switch to

Safe-Lock, and for a good reason."

During trochoidal milling operations, where the cutting speed and axial depth of cut can be increased through

software support, productivity is significantly improved. However, the increased cutter engagement and cutting forces that result from the higher cutting performance create a situation where tool pullout can occur easily. Prior to Safe-Lock, this problem was prevented with Weldon shanks and chucks. However, customers had to sacrifice speed and accuracy due to the nature of this clamping system.

A shrink-fit chuck with Safe-Lock offers the same safety as the Weldon system, but provides the additional advantage of accuracy and balance. The ideal balancing and runout characteristics of the shrinking technology in combination with the clamping safety of the Safe-Lock system permit greater productivity achieve through faster permissible speeds and increased tool life all with complete tool security assurance.

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- flash

flash

Thin web or film of metal on a casting that occurs at die partings and around air vents and movable cores. This excess metal is due to necessary working and operating clearances in a die. Flash also is the excess material squeezed out of the cavity as a compression mold closes or as pressure is applied to the cavity.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.