More than 150 U.S.-based robotics researchers contributed to the 2016 edition of the report titled “A Roadmap for US Robotics From Internet to Robotics.” Released Oct. 31, the document calls for improving policy frameworks to safely integrate new technologies, such as self-driving cars and commercial drones, into everyday life. The document also advocates for increased research efforts in the field of human-robot interaction and for more STEM (Science, Technology, Engineering and Math) courses for students.

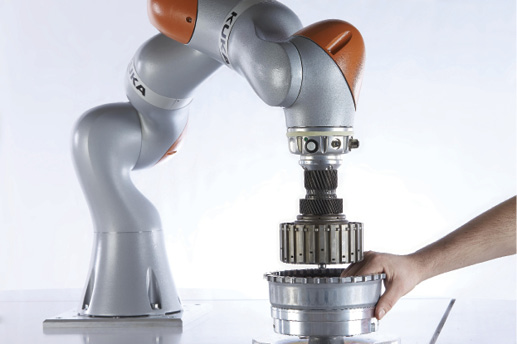

There’s no risk of injury with a collaborative robot. Here, a worker safely puts his hand in the path of a cobot as it assembles a gear. Image courtesy KUKA Robotics.

The document’s authors call for research to create more flexible robotic systems to accommodate the need for increased customization in manufacturing—and warn that there is a risk to falling behind in this global competition.

“Ambitious foreign competitors are investing in fundamental research and education that will improve their manufacturing processes,” the paper states. In contrast, the U.S. share of the global total of R&D funding “has dropped significantly, to only 30 percent.”

Specifically in robotics and manufacturing, global competitors are dwarfing U.S. investments. “Korea has been investing $100M per year for 10 years (2002–2012) into robotics research and education as part of their 21st Century Frontier Program,” the document reports, while the European Commission has invested more than $1.5 billion across two programs in manufacturing and robotics. “Japan is investing $350M over the next 10 years in humanoid robotics, service robotics and intelligent environments,” it notes, adding that Japan has also announced “a major push” in robotics with a 5-year investment of $1B for industrial robotics.”

The document also has good news, citing data that shows U.S. productivity, investments in automation, robotics and employment numbers have all been rising concurrently, and the report makes the case that a large increase in the use of robotics in manufacturing doesn’t have to mean job losses.

The expansion of robotic systems in industry must overcome two major obstacles, the road map states. Researchers need to develop user interfaces that will allow workers to operate robotic systems with little or no training. Also, the manipulation skills of the robots themselves need to improve dramatically, to the point that their dexterity at least matches a young child’s.

The document also calls for building a common, shared research infrastructure for robotics in the U.S. The research network would expand existing sites, with a focus on testing autonomous driving, medical and health care robotics, micro- and nano-robotics, agriculture robotics, unmanned aerial vehicles and underwater robotics. Each site would need about $3 million to accomplish this goal.

The 2016 U.S. Robotics Roadmap is partially sponsored by the National Science Foundation, the University of California San Diego, Oregon State University and the Georgia Institute of Technology. The entire report is available at http://tinyurl.com/robotics-roadmap.

Related Glossary Terms

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.