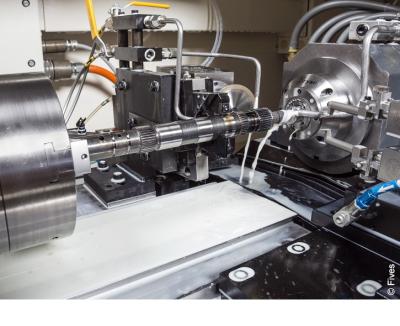

Fives introduces the next product out of its ID/OD line-up to the market. The Landis-Bryant UL2 is an internal high speed production grinder, ideal for processing bores, faces and contours of bearing rings, valve lifters, gears, universal joint cups and CVJ components, especially suitable for machining workpieces with an external diameter of up to 177 mm.

The Landis-Bryant UL2 has been designed specifically for high-speed, high-precision grinding of internal diameters. With this single purpose firmly established, performance compromises have been eliminated. The machine’s unique torque tube bed design combined with a “flow-through” system that circulates oil and coolant through the base provides ultimate rigidity and outstanding thermal stability to the Landis-Bryant UL2 grinding system.

Independent slides in X and Z, each mounted directly to the machine bed, make for an extreme low center of gravity. The machine’s round-bar hydrostatic slide ways in each axis provide an extremely stiff system with minimum friction. Fives uses high resolution servo motors that are directly coupled to super precision ball screws for precise and reliable positioning throughout the entire production cycle.

Whether your application calls for a diaphragm or collet chuck, a shoe centerless magnetic chuck setup, or a disc drive roll centerless arrangement, the Landis-Bryant UL2 allows for various machine configurations. Furthermore this machine offers automatic workpiece loading solutions for many applications as well as In- and Post-process gauging in a very compact setup. Other features of the Landis-Bryant UL2 grinder include acoustic emission monitoring system (AEMS), automatic taper adjustment, Fanuc i Series as well as various dressing options.

Fives’ ID grinding systems are equipped with Landis-Bryant spindles that contain super-precision bearings and permit operation at extremely high speeds. They are powered by in-house-designed induction motors to provide superior performance for efficient machining.

“We were able to secure a multi machine order from a leading manufacturer of high precision engine components following the acquisition in 2015.” says an enthusiastic Ron Wood, executive director business development at Fives Landis Corp. “All machines have successfully completed the run-off at our Hagerstown (MD) facility and being currently commissioned at the customer’s production plant.”

Contact Details

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- magnetic chuck

magnetic chuck

Workholding device used on surface grinders and milling machines for holding ferrous parts with large, flat sides. Holding power may be provided by permanent magnets or by an electromagnetic system. See chuck.