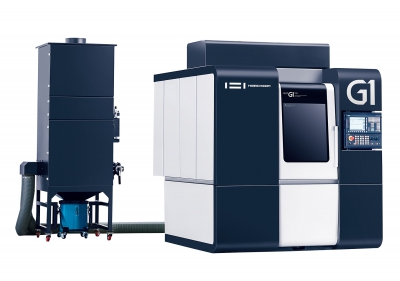

Hwacheon Machinery America Inc.’s new Hi-M G1 vertical machining center is specially designed to cut graphite. Its quick and precise performance makes it an ideal choice for dry cutting graphite electrode material used in die mold work, according to the company. The rigid, yet compact structure, with a design based on 3D/FEM analysis, and wide LM guides for X/Y/Z axes, ensures accuracy.

For high-speed operation, the 24,000-rpm spindle is integrated with a high-power motor, and without any parts to transfer power between the motor and spindle. This design minimizes vibration, noise and power loss during high-speed rotation. In addition, a bearing grease lubrication system and synchronous temperature control decreases the influence of external temperature variation and improves smoothness.

For quality results, the Hi-M G1 is engineered with a dustproof/waterproof spindle and an advanced dust reduction system. This system includes a sealed roof design that collects the fine dust generated during the machine process. A dustproof air curtain system prevents dust inflow into each axis. Included as standard, the dust collector operates with 5HP air volume. The design of the Hi-M G1 door enables convenient cleaning.

The user-friendly Hi-M G1 includes a Siemens-828D Controller. It provides flexible, interactive programming, as well as controls that enable high productivity.

Hi-M G1 specifications include a spindle coolant system, an HSK–E40 spindle taper, a 29.52" x 23.62" table with an 881.84 lb. load capacity and a 16-tool ATC. The machine occupies just 83.26” x 87.8” of floor space and weighs 10,582 lbs. The dimensions of the dust collector are 38.18” x 38.18”.

Another application of the Hi-M G1 is graphite automotive parts machining.

Contact Details

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.