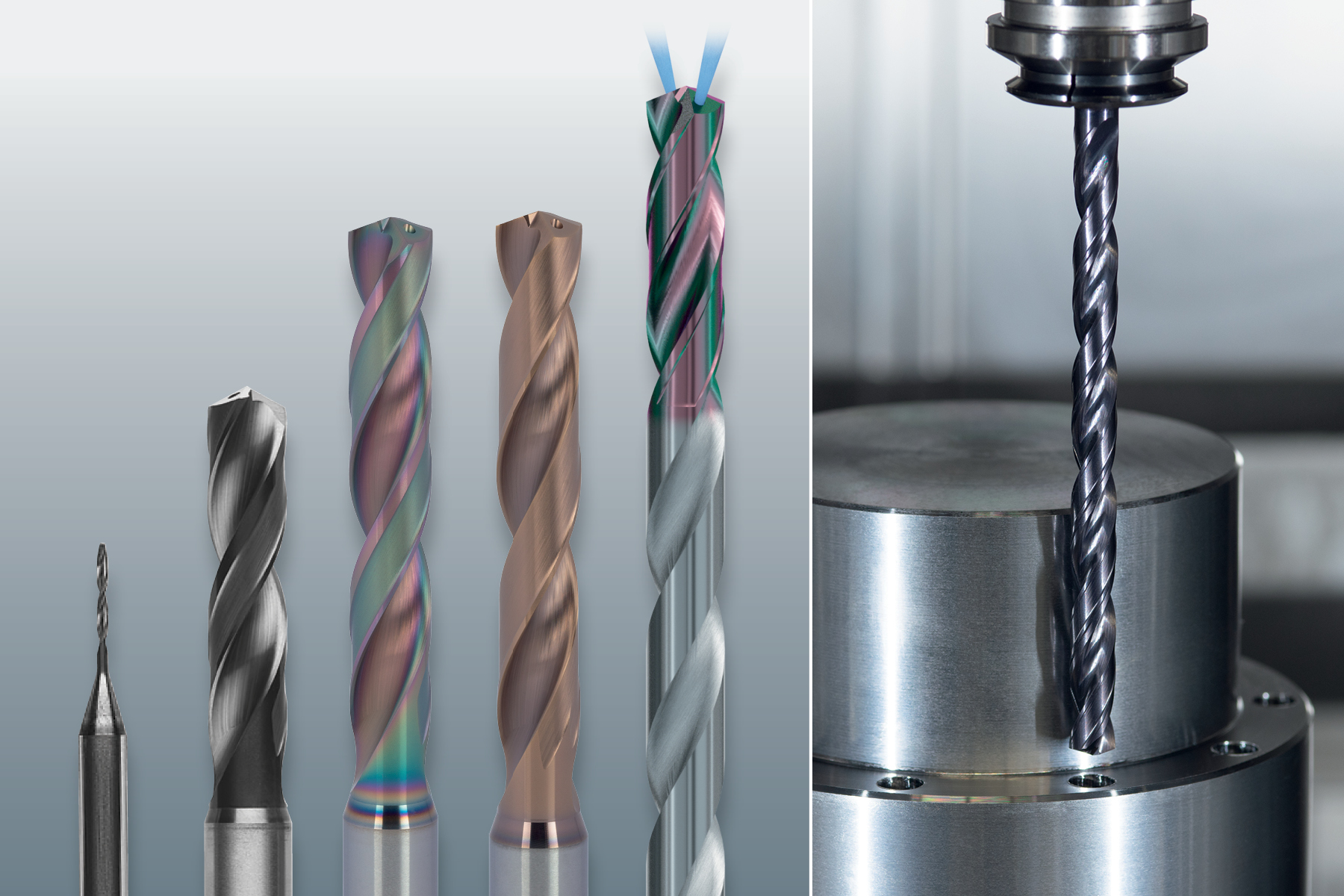

Emuge-Franken USA, a manufacturer of high-performance taps, thread mills, end mills, drills, and other rotary tools, has expanded its solid carbide drill program in North America, introducing SteelDrill and InoxDrill, two all-new lines of drills.

In addition, the range of its MultiDRILL line has expanded with the addition of 8XD lengths and new Micro Drills. Also, EF-Drill is now available in 12XD. For more information, and to download or order the all-new EMUGE Drill Catalog click here.

“Our significantly expanded drill program with the addition of over 1,000 SKUs offers customers even more comprehensive holemaking solutions, including two new lines of high performance drills,” said Dylan Bowles Product Director, Emuge-Franken USA.

SteelDrill line

The new EMUGE SteelDrill line is optimized for steel and cast materials, while also performing efficiently in hard and non-ferrous metals, the company said. Key features include a concave primary cutting edge with optimized edge preparation, coolant-through capability, and a double-margin design for excellent stabilization and high-precision hole quality. A proprietary EMUGE coating ensures smooth, high-speed cutting and exceptionally long tool life. This high-performance drill line is available in 3XD, 5XD and 8XD lengths, with diameters from 0.1181" to 0.7874" (3.00 to 20.00 mm), totaling 548 SKUs.

InoxDrill Line

The new EMUGE InoxDrill is designed for stainless, aluminum, titanium, and nickel alloys. It features a single-margin design to reduce material adhesion and improve hole guidance, along with a custom EMUGE coating and polishing process. Like the SteelDrill, it includes coolant-through capability and a concave primary cutting edge with optimized edge preparation for superior performance. The InoxDrill line is available in 3XD and 5XD lengths, with diameters from 0.1181" to 0.7500" (3.00 mm to 19.05 mm), totaling 372 SKUs.

MultiDRILL Line

In addition to existing 3XD and 5XD lengths, the new EMUGE MultiDRILL line is now available in 8XD lengths in diameters from 0.1181” to 0.6299” (3.00 mm to 16.00 mm), a total of 172 new SKUs. MultiDRILL is the ideal go-to drill for job shops running a many materials—or even in production environments.

The MultiDRILL line also includes new 6XD Micro Drills ranging from 0.0394”. (1 mm) up to 0.1160”. (2.95 mm) in diameter. The new MultiDRILL Micro Drills feature an advanced flute profile designed to enhance chip evacuation of varying materials, and have a radius cutting edge for high shearing action. A specialized point geometry generates short chips and guarantees optimum performance. For heat and wear resistance, MultiDRILL Micro Drills have ALCR-99 coating.

EF 12XD Drills

EMUGE high-performance EF-Drills are now available in 12XD lengths in diameters from 0.1181” to 0.5512” (3.00 mm to 14.00 mm), a total of 47 new SKUs. EMUGE EF-Drills are designed for premium performance in demanding applications and materials for deeper hole drilling that require straightness and surface quality beyond a standard high-speed steel drill

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- edge preparation

edge preparation

Conditioning of the cutting edge, such as a honing or chamfering, to make it stronger and less susceptible to chipping. A chamfer is a bevel on the tool’s cutting edge; the angle is measured from the cutting face downward and generally varies from 25° to 45°. Honing is the process of rounding or blunting the cutting edge with abrasives, either manually or mechanically.

- polishing

polishing

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.