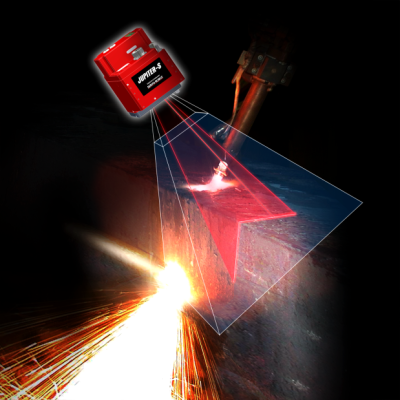

Servo-Robot has launched the Jupiter-S robot-vision system specially designed for real-time edge and feature detection and tracking in very harsh environments, such as oxy-gas, plasma and high-power laser metal cutting. In this patented laser triangulation technology, a scanning laser beam provides a high-resolution programmable measurement scan of the object highly immune to process noise and flying molten metal.

Special optical filtering techniques and embedded automatic control of the camera make it suitable to measure metallic surfaces of various finish.

Jupiter-S also includes an embedded video camera with LCD filter, allowing easy programming of the robotic applications and remote monitoring of the process in operation. Liquid or air cooling together with a pressurized front shield protect the camera from heat, fume, hot spatter and dust, reportedly ensuring reliable and continuous robotic operations in the harshest industrial environments.

JUPITER-S is used in many adaptive robotic applications, including beveling of metallic parts. This ensures a high speed and high quality of bevel dimensions despite part position error or part distortion.