Sandvik to acquire 3D metrology software provider Verisurf

Sandvik to acquire 3D metrology software provider Verisurf

Sandvik has signed an agreement to acquire Verisurf Software Inc., a US-based 3D metrology software solutions provider.

Sandvik has signed an agreement to acquire Verisurf Software Inc., a US-based 3D metrology software solutions provider.

Verisurf will complement and enhance Sandvik's position in industrial metrology and strengthen the combined digital manufacturing offering to small and mid-sized manufacturers (SMEs). The company will be reported as a separate business unit within business area Sandvik Manufacturing and Machining Solutions.

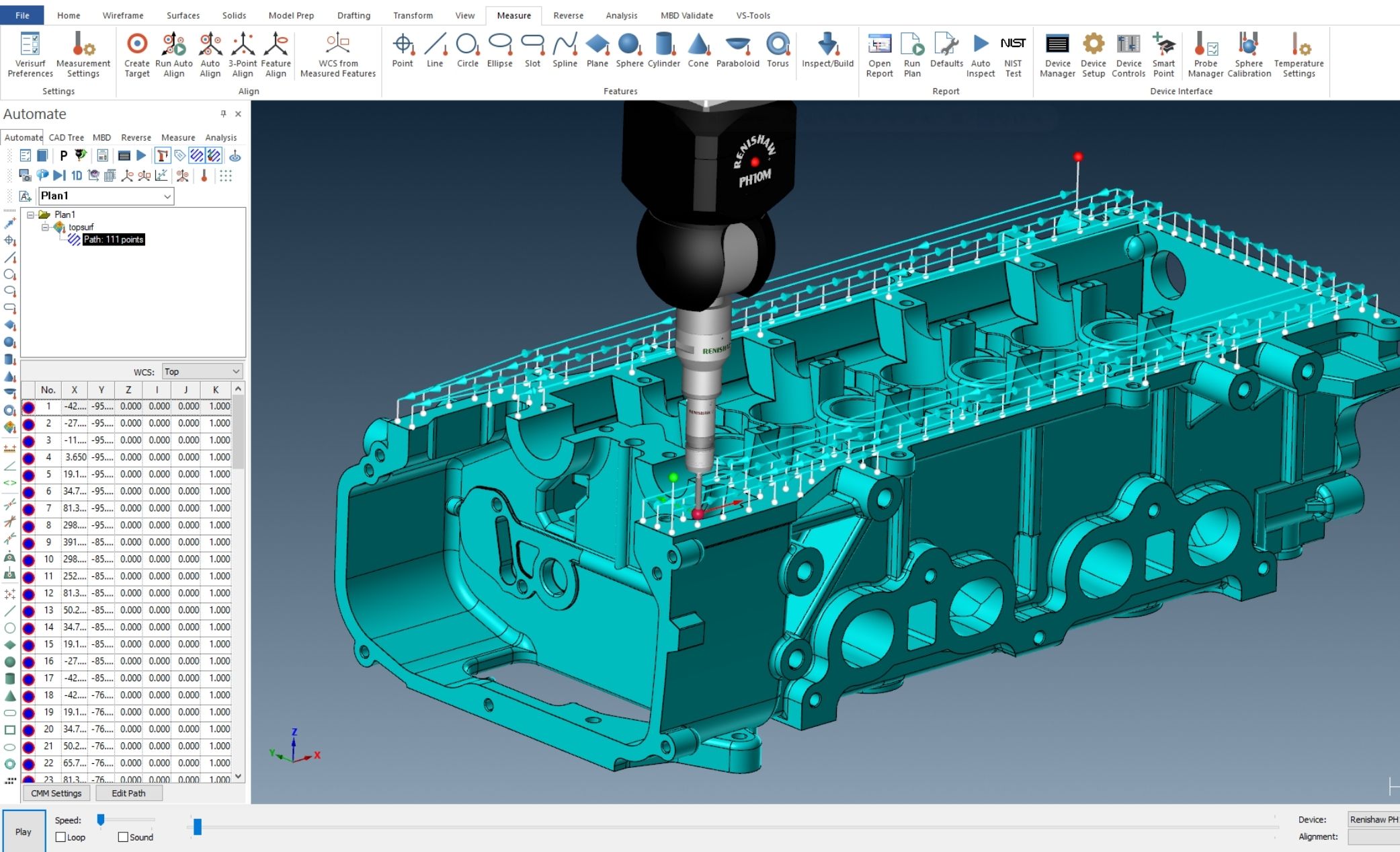

Verisurf is principally active in the North American market. The company serves a diverse customer base of around 1,500 companies — SMEs as well as larger customers — with exposure in segments such as aerospace and defense. Verisurf offers modular-based easy-to-use software solutions for quality inspection, assembly guidance, and reverse engineering, that are built on the Mastercam Design (CAD) platform.

"Verisurf will strengthen our metrology offering and ability to support the growing customer demand for precision measurement and quality assurance in manufacturing. The acquisition fits very well with our strategy to grow in digital manufacturing and provide comprehensive solutions for our customers to drive efficiency and productivity," said Stefan Widing, president and CEO of Sandvik.

Verisurf has 44 employees and is headquartered in Anaheim, California. In 2024, the company had revenues of approximately SEK 130 million (USD $12 million). The impact on Sandvik's EBITA margin and earnings per share will be limited. The parties have agreed not to disclose the purchase price. The transaction is expected to close during the second quarter of 2025, subject to customary regulatory approvals.