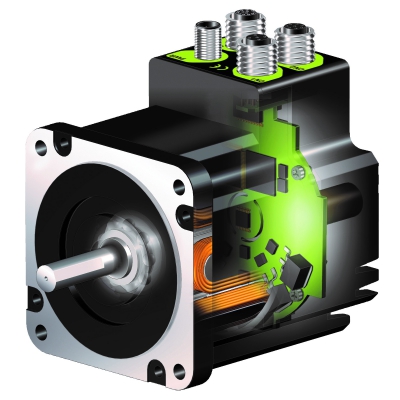

JVL presents a new innovative closed-loop stepper motor technology for its NEMA 23 & 34 integrated stepper motor range from 0.1 to 12 Nm. JVL says its closed-loop integrated stepper motors, QuickStep, provide higher torque, faster acceleration, torque control, stall free operation and quieter movements than traditional step motor systems.

QuickStep do this with greater efficiency and less motor heating because motor phase current are regulated up and down according to need. Performance of JVL closed-loop steppers are similar to servo motors, but with higher torque and often without need of gearbox, resulting in a more inexpensive solution. Design safety factors have always been high for stepper motors to ensure stall-free operation – now with QuickStep closed-loop control design can be very close to the limit resulting in even lower costs.

QuickStep is a true closed-loop control system that compensates step angle errors during a movement and correct errors within a full step. If load becomes too high speed is lowered and position errors will always stay within two full-steps. Smart digital design and very high update rates (36 MHz) means there is no need of any manual adjustment or setup. It works like a perfect stepper motor benefitting from the servo motor technology.

Advantages compared to open-loop stepper motors

- Position feedback and control

- Fast and easy commissioning. No tuning needed

- No stalling. No step losses at all

- Torque control

- Much faster positioning and more cycles per second

- Increased efficiency and thereby much lower temperature

- Shorter settling time

- Controls higher inertias than open loop steppers

- Higher load tolerance

- More quiet operation (lower acoustic noise)

- Longer lifetime due to lower temperature

- Correct positioning without overshoot and oscillation

Advantages compared to servo motors

- Very high Torque at low speed. Often 3-4 times higher in same motor flange size

- Very high ratio-of-inertia, often up to 40:1

- Faster commissioning. No tuning needed

- Lower price. Same price as open loop steppers

- Totally stiff at standstill. Full holding torque

- Direct drive without gearbox (better and more precise torque control)

- Correct positioning without overshoot

- No oscillation

- Very short settling time

Benefit in these application from closed-loop stepper motors

- Multiple axis applications (RS485, CANopen)

- Industrial Ethernet: Profinet, EtherNet/IP, EtherCAT, Powerlink, Modbus TCP, SERCOS III

- Magnetic or Absolute Encoder Feedback

- Positioning tasks with load changes

- Applications that require quiet operation, short settling times and precision positioning

Applications include

- Winding applications

- Belt drives (start/stop, positioning)

- Dosing pumps and filler systems

- Semi-conductor mounting

- Wafer production

- Textile machines and industrial sewing machines

- Robotics

- Testing and inspection systems

Contact Details

Related Glossary Terms

- overshoot

overshoot

Deviation from nominal path caused by momentum carried over from previous step, as when a tool is rapidly traversed a considerable distance to begin a cut. Usually applies to CNC machining and is prevented if the control has the appropriate look-ahead capability. See look-ahead; undershoot.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.