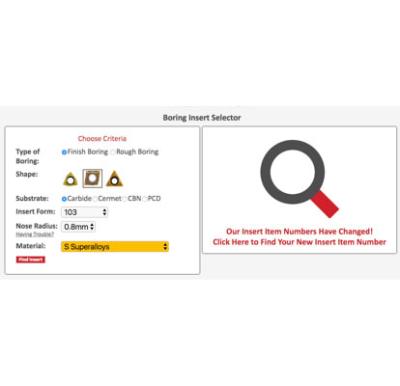

Allied Machine & Engineering announces its newest online tool: the Boring Insert Selector. This resource saves valuable time by simplifying the boring insert selection process and ensures machinists are provided the correct boring insert for each job’s unique details. Rather than hunting through multiple catalog pages to narrow the field of possibilities, this online tool guides the user to the correct boring insert for the job in just six easy steps.

Allied’s Boring Insert Selector allows end users to select job-specific criteria from drop-down menus. Criteria include roughing/finishing, shape, substrate, form, nose radius and material to be machined. If users are unsure which nose radius to select for their finish boring application, this tool provides tips on formulating that as well. Once all criteria are selected, users simply click “find insert” to reveal the best choice for their unique boring application. The online tool also provides an image and link for more detailed information and pricing.

“Even the most precise boring tool in the world can be a dud if you are using the wrong insert for your application. Allied’s Boring Insert Selector can maximize the performance of your modular boring investment today” said Ben Morrett, product manager for both Criterion and Wohlhaupter boring lines at Allied. “We are always looking for ways to help customers achieve success. This selection tool will save folks time and money by providing them with the right boring insert, the first time, for each application they face.”

The Boring Insert Selector is for anyone utilizing Wohlhaupter, Criterion or other boring tools.

Contact Details

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.