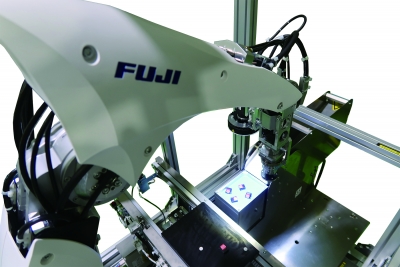

Designed for the assembly of manufactured parts, Fuji Machine says its SmartWing Robots are revolutionizing the industry with remarkably easy, efficient and accessible automation.

Engineered with cutting edge technology, SmartWing Robots offer unprecedented speed and ease of setup. The elimination of teaching with physical guidance reduces setup time by 40 percent compared to contemporary systems.

In addition, with the inclusion of preprogrammed actions, or Waza, setup only requires entering “what” and “where” information to create robot actions. This drastically reduces the time required to create robot programs. The SmartWing’s Coordinate Compensation Technology ensures absolute positioning accuracy and allows movement specification by simply entering coordinate instructions. A Vision Data function detects when items shift position and compensates movement accordingly.

For efficient, quick-start production, the SmartWing’s included Vision System is precalibrated with the necessary settings for immediate use upon installation. The robot features a high-resolution color camera that detects even highly reflective metal workpieces. Data Matrix, QR codes, and other 2D codes are supported and can be read by the SmartWing.

Adding to the efficiency of the SmartWing is its ease of operation. No special training is required to create vision processing data and robot movement data. Included as standard with the robot is a Job Editor tool for offline job creation, which enables high-mix production. Creating a production job requires only targeting the workpiece, accessing Waza from the Job Editor library and entering the working coordinates. SmartWing’s Shape Editor tool allows for the easy creation of vision processing data. A simple selection of the workpiece area automatically extracts contours and colors. An optional SmartWing Simulator tool is available for the accurate reproduction of robot movement on a computer. Using this tool, cycle time and interference can be checked before actually moving the robot.

A Robot Cell Kit is included with the SmartWing for the fast and easy assembly of a flexible Robot Cell system.

Some Smart Factory applications for this robot include workpiece sorting, accurate long screw placing, loose part sorting and arranging and dual robot cooperation for inserting and tightening screws.

Contact Details

Related Glossary Terms

- vision system

vision system

System in which information is extracted from visual sensors to allow machines to react to changes in the manufacturing process.