Mitsubishi Electric Corp., an established MC Machinery automation solutions partner, has teamed up with ASTES4 to offer its laser automation solution. This multifunctional system is the first fully integrated system capable of controlling the entire production process from loading, cutting, sorting and unloading through to the storage of finished parts.

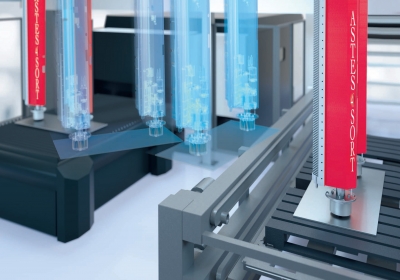

The system utilizes four cartesian grippers for loading, unloading and the sorting of parts. Each gripper is capable of using vacuum or magnetic tools in a variety of shapes and sizes to produce a more effective sorting speed. The process sorts the parts into kits, and its wide variety of options allows for different material thicknesses to be kitted on the same pallet. Downstream processes are taken into account to provide seamless integration into the production process.

“We are very excited to unveil the ASTES4 system at FABTECH,” stated Shane Herendeen, North American sales manager – fabrication division. “This new automation system will change the way companies use their machines and sort their parts, and is a huge step forward for our entire industry.”

Its software automatically optimizes and manages the production process through to storage, without the user having to intervene. Remote access and a camera system allow for continuous monitoring and intervention if needed.