Size matters, and the MasterPrint 3D printer with milling capabilities is living large. Built by Ingersoll Machine Tools Inc., Rockford, Illinois, the printer is part of a new line of additive manufacturing equipment that seamlessly programs, simulates, 3D-prints and mills extra-large composite parts in a single piece.

With the University of Maine, MasterPrint 3D-printed a hollow beam structure 7 m long × 1.6 m wide × 1.8 m tall (23'×5.2'×5.9') with over 2,155 kg (4,751 lbs.) of carbon fiber-reinforced acrylonitrile butadiene styrene, said Piergiorgio Assandri, business director of composites and additive at Ingersoll Machine Tools. The machine prints a wide array of materials in various orientations and finishes parts with five-axis milling. The company says part manufacturers can benefit by combining their traditional skills with MasterPrint’s disruptive processes.

He said the platform can handle polymers and aluminum and has a working volume of 12 m × 4 m × 2.5 m (39.4'×13.1'×8.2'). The five-axis milling head runs at 25 kW (33.5 hp) and 18-rpm max spin using an HSK 63A toolholder. Designed for fast prototyping and making aerospace and naval molds, the printer can serve a wider market, namely companies needing wide and tall parts that are cost-effective, quick and reliable. MasterPrint uses a Siemens Sinumerik 840D sl CNC. Everything is fully automated, including changing cutting tools.

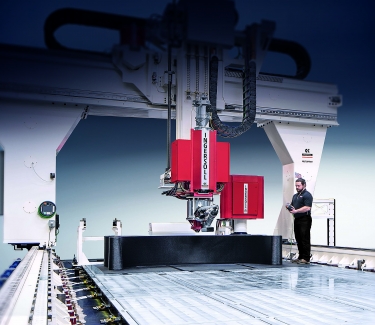

An employee works with the MasterPrint 3D printer and five-axis milling machine. Image courtesy of Ingersoll Machine Tools

Aerospace manufacturers have selected thermoplastics capable of enduring the autoclave process and used MasterPrint to make durable molds for production. Until recently, Assandri said, the molds were milled using Invar steel, an expensive nickel-iron alloy with minimal thermal expansion coefficient, which preserves mold geometry during the autoclave process that wings, fuselages and nacelles go through. The lead time for Invar molds was months. Once the molds were made, any refinements to them for the geometries of the related aerostructures added more time and expense. With MasterPrint, lead time is shortened to weeks, he said, and manufacturing costs are reduced by 90%.

“At pretty much the same time, the naval sector … saw the opportunity to print and mill — first their own molds and then their entire boats — with MasterPrint,” he said. “Real boats, tens of meters long, (were) used as models to validate the hydrodynamics of their hulls before building them out of fiberglass.”

In addition, Assandri said the automotive industry plans to use MasterPrint to print and mill electric vehicle chassis and truck cabins.

For more information about Ingersoll Machine Tools, call 815-987-6000 or visit www.ingersoll.com.

Contact Details

Related Glossary Terms

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- milling machine ( mill)2

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.