Article from ANCA

At ANCA, the company's success has been underpinned by listening to its customer’s needs. Rather than only offer a standard product range, the builder of grinding machines often delivers custom solutions. ANCA’s engineering team can custom design mechanical, electrical, software and process solutions to enhance the standard product range and meet unique customer requirements.

Simon Richardson, ANCA product manager, said, “Developing new technology that directly addresses customers’ requirements, hopefully helping you get ahead of your competition benefits everyone. Our founders are often heard reflecting that some of our greatest product breakthroughs have originated from custom projects.”

More recently, AB Tools Inc., a Lincoln, California-based specialist tool manufacturer, requested a solution to manufacture special carbide inserts. The company was seeing a growing demand for the product and asked ANCA to supply a solution based on an MX7 Linear for autoloading and grinding special inserts as existing machinery and processes were not versatile enough for AB Tools to successfully meet its demands.

Alfred Lyon, AB Tools shop supervisor, said, “Both Jon Baker, the president at AB Tools, and I were extremely impressed with the whole process. From our own testing to having Simon Richardson come out and scope out our needs and what we wanted to accomplish. Followed by several emails, a discussion with Pat Boland himself and then flying to Melbourne to meet with the incredible customer solutions team who then took our requirements and ran with it.

“Lastly, and probably the most amazing and important part, ANCA sending out engineers to iron out all last-minute details. Basically, our goals were not merely met but exceeded!”

The engineering team was requested to deliver a solution that was able to:

- Autoload and grind a range of AB Tools shear hog inserts.

- Perform grinding operations in one setup.

- Meet cycle time requirements.

The custom solutions engineering team delivered an enhancement to the ANCA MX7 with Robomate. New designs developed included:

- A modification to the loading system with custom pallets to suit the inserts. The custom pallets can hold up to 442 inserts, this capacity can easily be increased by ordering the four pallet upgrade option available on the MX7 Robomate.

- A modification to the robot gripper head allows the robot to pick up and handle the insert/nail combination.Robot loading software was developed to enable to the machine to pick up the insert and load and unload the nail via an interchange station.

- Custom anvil nose work holding to clamp the inserts, with the added benefit of a variable force drawbar system. This drawbar allows flexibility to grind different sized inserts and to effectively clamp different sized tools.

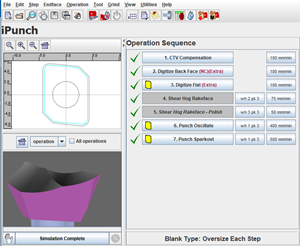

- A software interface to allow for the adjustment of specified insert parameters, including corner radius, periphery relief angle and rake face dimensions. Software also verifies the insert orientation prior to grinding.

Lyon concluded: “ANCA impressed me from day one. Creating basically a whole new type of machine for AB Tools Inc. is not merely impressive, it is extraordinary. We could have purchased another machine just like the one we were using but we asked ANCA for help because we wanted to expand our capabilities and simplify our process. This new machine has exceeded both desires.”

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- relief

relief

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.