Article from Fact.MR

Amidst the growing demand from automotive industry, metal forging market is set to witness a robust growth rate of more than 7%. Within the automotive sector demand is soaring for high-performance forged components for cars, trucks and commercial automobiles, thus augmenting the demand for metal forging. Metal forging is witnessing a surge in automotive applications on back of its durability, strength and reliability.

Key players in the metal forging market are focusing on expanding production capacities to expand their footprint and ensure consistent quality. Large scale R&D initiatives are being undertaken in metal forging processes and raw materials.

Key Takeaways of Metal Forging Market

- Carbon Steel is the most in-demand raw material. Its popularity can be attributed to the high-performance qualities of carbon steel such as ductility, yield strength and impact resistance capacity.

- Magnesium offers the most lucrative revenue opportunities with a positive CAGR of more than 9%. Governments around the world are introducing stringent regulations to promote the use of high-performance materials such as magnesium for aerospace and defense manufacturing, which is further augmenting its demand.

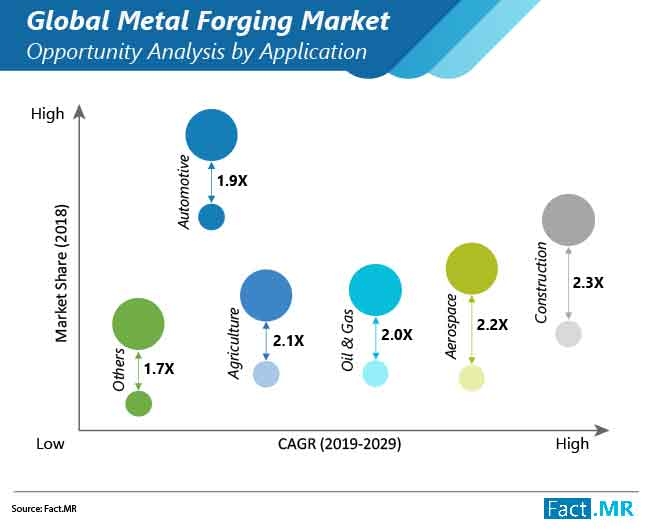

- Application of metal forging in construction will gain two times the traction from companies on the back of infrastructure development in emerging countries to support the economic needs.

- Automotive remains the leading application segment of metal forging. The production of electric cars is demanding specialized metals to be forged with precision and quality.

- East Asia is the leading global region for metal forging manufacturers with more than 40% of the market share.

- South Asia presents beneficial growth opportunities since countries in South Asia, such as Singapore and Indonesia, need metal forging services to cater to their automotive and manufacturing industries, respectively.

“Trends such as digital thermomechanical analysis and integration of IoT with forging technology will bring about disruptive changes in market. Powder metallurgy and part manufacturing segment is expected to drive demand for forged metal products during the forecast period,” the report stated.

Automation and Integration of 3D Technology to Heighten Adoption of Metal Forging

Automotive industry is expected to drive continuous market demand for metal forging on back of development of alternative energy automobiles. With an increase in buying potential of millennial, automotive industry will witness a surging demand for electric cars and other automobiles that support transportation of consumer products globally.

Opportunities lie in powder metallurgy and parts manufacturing for oil, gas and nuclear energy power plants worldwide. Market players are following market-trend-based strategies by adopting the latest developments in forging processes such as integration of 3D technology to enhance quality assurance, and adoption of automation to improve manufacturing processes. Major companies are focusing on collaborating across verticals and industries to leverage future growth potential in developing economies.

Related Glossary Terms

- ductility

ductility

Ability of a material to be bent, formed or stretched without rupturing. Measured by elongation or reduction of area in a tensile test or by other means.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- powder metallurgy

powder metallurgy

Processes in which metallic particles are fused under various combinations of heat and pressure to create solid metals.

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.

- yield strength

yield strength

Stress at which a material exhibits a specified deviation from proportionality of stress and strain. An offset of 0.2 percent is used for many metals. Compare with tensile strength.