Just as making a mark is important in life, it’s also an essential element in many product manufacturing processes. Product marks can take a number of forms, including logos, QR codes and serial numbers. In some industries, putting a distinctive mark on every part is vital for traceability purposes.

The problem, however, is that common static marking techniques aren’t a good fit for modern automated manufacturing processes focused on minimizing cycle time. But if their budgets allow it, factories have another option: fully automated laser marking systems designed for integration into manufacturing lines. Marking “on the fly” as parts move along the line, these systems can do their job without slowing production.

Marking on the fly also can be done with ink, but companies that sell laser systems say their technology is a better choice. For one thing, they point out that lasers make more durable marks on parts.

Lasers leave indelible marks on parts. Image courtesy of Trumpf

“With the laser, you are changing the material and getting a more scratch-resistant mark compared to an inkjet, where the mark is only on the surface and not in the surface,” said Albert Jung, marking technology specialist at Trumpf Inc. in Farmington, Connecticut. “You can scratch off an ink, but a (laser) mark needs to be grinded off a steel part.”

In addition, laser marking companies say their systems are more reliable than their inkjet counterparts, which have nozzles that can clog and make it difficult to mark.

As a result, “they continuously need maintenance,” said Jerome Landry, application specialist at Laserax Inc. in Quebec City.

By contrast, he said a laser system requires no maintenance.

“You install it,” Landry said, “and basically you have something that works without issues.”

Then there’s the consumables contrast.

Sellers of ink-based systems “really make their money off the consumables — the ink, solvents and other things used in that process,” said Rick Jones, lead support engineer at Pryor Technology Inc. in Ashland, Virginia. But in laser marking processes, “consumables are virtually zero.”

Laser marking is a fully automated process that can mark a part in a fraction of a second. Trumpf’s systems use software to calculate the speed of a part-carrying conveyor belt and align that with the speed of the laser mirrors, which are moved by a pair of motors. This allows the system to mark parts while they are in the laser’s scan field, Jung

explained.

Although users don’t have to pay for ink and other consumables, the laser is a big-ticket item. Landry said the cost of a laser on-the-fly marking system ranges from approximately $60,000 to $120,000 compared with roughly $10,000 to $30,000 for an ink system. He added, however, that laser systems eventually make up this cost difference through savings on ink and other consumables over time. This could take a year in high-volume manufacturing operations, he said, and “more like two to three years” in settings where production is slower.

Production Considerations

Slowing down a line for marking means slowing production as well.

Therefore, “when integrating a laser for marking into an automated cell, you want to make sure the extra step is not reducing the volume capabilities of the process,” Landry said.

One way to speed up laser marking to meet production requirements is to opt for a higher-power laser.

“Up to a certain point, this is scalable,” Jung said. “So if your mark would take one second with a 10 W system, you can scale up to a 20 W system and reduce the time to half a second.”

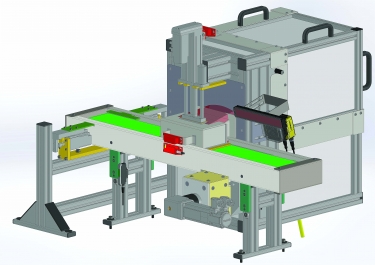

This custom on-the-fly laser marking system was designed to meet the requirements of a particular production process. Image courtesy of Pryor Technology

Jones said a 20 W system is “very standard” for industrial marking applications, though he believes that Pryor Technology has provided laser power as high as 300 W to customers.

The downside to boosting laser power, of course, is that it also makes the laser’s price tag even heftier.

“Cost goes significantly higher as you up the wattage to meet your target cycle time,” Jones said.

For those who want faster marking but already are using the highest available laser power, other options can help align the marking process with production goals. One alternative is to purchase a second laser marking system. Jung said the two systems can be deployed in a couple of different ways. One approach is to use both systems in the same line, with the first laser that the components encounter marking every other part and with the second laser marking the remaining parts farther downstream. Or manufacturers can use two conveyor belts and a laser marking system with each.

Another consideration when time is of the essence is the mark itself.

As a part moves through the marking area, Jones said, “you have a limited amount of time in which you can effectively mark it, which is driven by the application. Some people have 15 to 30 seconds; some have half a second. When you only have a half a second, sometimes you have to make compromises on how much you mark.”

This means that users of on-the-fly marking systems might have to reduce the size of the logo or the individual characters in a mark and/or cut the amount of content in a mark. So, for example, instead of 12 characters that are each 4 mm (0.16") high, a mark may have to be reduced to five characters that are each 3 mm (0.12") high to meet

application requirements. Or instead of a bold black mark, time-conscious manufacturers might have to opt for a dark gray one.

Managing the Downsides

Tweaking the process to meet application requirements isn’t the only item on the to-do list for manufacturers that choose on-the-fly laser marking. Another aspect is figuring out how to deal with the potential danger posed by the laser in a production environment.

“With fiber lasers, one of the unique challenges is that human eyes can’t see the light,” Jones said. “It can detach your retina in a fraction of the time that it takes for you to even know that you blinked — and you are permanently blind. So often you have to shield the system or enclose the entire room away from human eyes.”

When a Laserax system is installed, the marking area is partially enclosed to ensure that it is “Class 1 in terms of laser safety,” Landry said.

This means that the machine area is safe for personnel not wearing protective gear.

Besides being hazardous to humans, laser marking can have an unacceptable impact on certain parts.

LXQ fiber laser marking systems are designed for fast integration into production lines. Image courtesy of Laserax

Regarding the effect of laser marking on part quality, “it’s fine for most industrial applications because it only creates a surface roughness of about 30 µm (0.001"),” Landry said. “If you put your finger on the marking, you will feel that it is kind of rough. But it is not dug in the material and doesn’t really change anything in the structure.”

Nevertheless, he said, Laserax’s on-the-fly marking systems are not used by medical manufacturers because of that industry’s stringent surface finish requirements.

Makers of thin-walled parts in any industry should have concerns about laser marking. These manufacturers can mark on the fly, but they may have to accept a mark that’s very different from one they would put on sturdier parts.

“If you have a thin metal piece and want a very dark mark, you could do a black engraving that will evaporate 5 to 10 µm (0.0002" to 0.0004") on top of that part, but you are introducing a lot of heat,” Jung said. “If this warps the part, you need to change the process.”

For example, a manufacturer could switch to a delicate white engraving that would affect only the top 2 µm (0.00008") to 5 µm of the part surface.

“You are now introducing less heat but still creating a visible mark on the part,” Jung said.

A Valuable Role

Although best suited to high-speed production lines, on-the-fly laser marking can play a valuable role in many manufacturing settings.

“Anywhere you already have the product moving in an automated fashion and don’t want to take it out of that process for an additional operation, it allows you to do the marking right in line,” Jones said.

This is crucial because marking time can make or break some facilities. He said a plant that makes one jet engine component a month might have all the time in the world to mark products.

In other cases, however, if cycle time “is a tenth of a second over target, it can shut a factory down,” Jones said. “With marking on the fly, you can have almost zero effect on cycle time in the system.”

Contact Details

Contributors

Laserax Inc.

844-471-0144

www.laserax.com

Pryor Technology Inc.

804-496-6669

www.pryortechnology.com

Trumpf Inc.

860-255-6000

www.trumpf.com