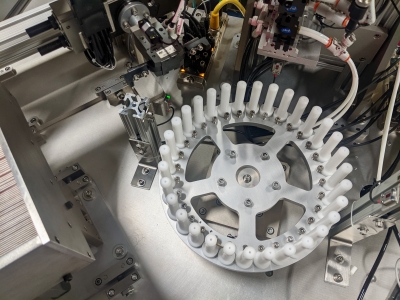

BOLD Laser Automation develops (Laser Process Micro Assembly) LPMA1000 Series, a small component modular assembly automation platform for precision laser welding skiving (material removal), and drilling. The laser-based LPMA series is for value-added assembly of products such as medical devices, microelectronic, microfluidics, and nozzle applications. With its compact and flexible tooling design, the advanced LPMA system can improve customer productivity. The LPMA revolutionizes modular laser process automation and promotes innovative, globally competitive opportunities for small to midsize niche manufacturers in the United States and Europe. LPMA series contains all beam delivery functions necessary to support the efficient operation of the laser, with integrated power measurement, beam diagnostics (option), laser attenuation, purge system, and quick optic change mounts. Customers will select configurations for bowl feeding, bin feed, pick & place automation, and machine vision. Central turntable and XY stage pallet configurations offer a modular approach for clients to quickly shift from one product family to another. The LPMA offers Fiber, UV DPSS and CO2 laser options.

“Through the capabilities of the LPMA series product line, BOLD once again empowers its customers to acquire and leverage leading-edge laser processes to scale their products,” said Todd Lizotte, president of BOLD Laser Automation, Inc. “The launch of the LPMA Series in the United States will provide significant opportunities for customers in numerous industries to boost throughput, shrink machine footprint and increase flexibility while eliminating time-consuming product changeovers.”

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.