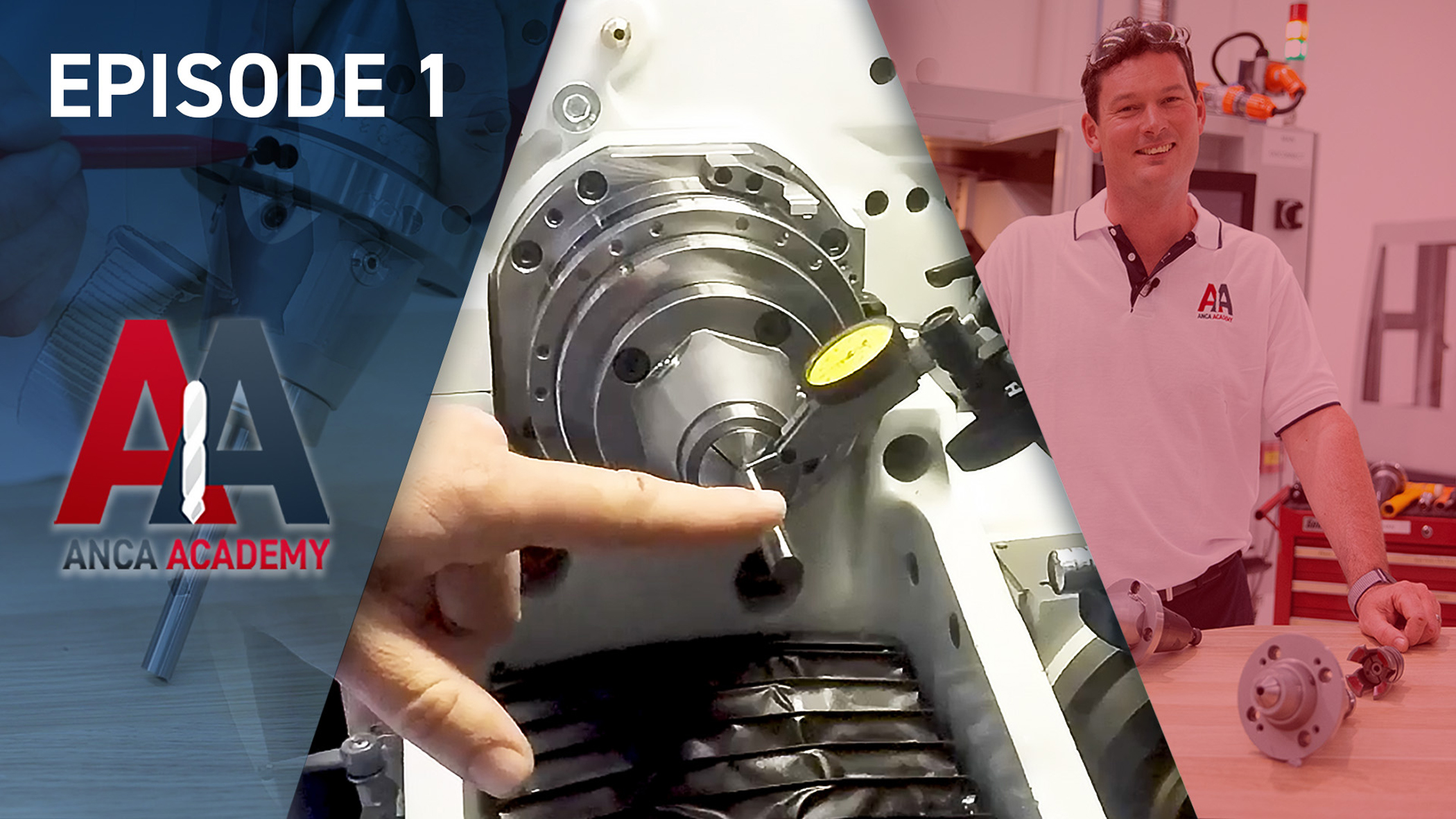

Each month, the ANCA Academy show will cover a different technical topic - from set up through to grinding. The educational videos will help ANCA machine users understand new applications and features.

Hugh Ingham, ANCA Mechanical Engineer hosts the new show and said: “I love working at ANCA because we design and apply really interesting and effective technology. It is important that we make sure we are helping our customers and those interested in getting into cutting tool grinding produce the best possible product faster, more accurately and at the lowest possible cost. The first episode will explain a PCA adaptor, how they work and how you can set your machine up for long and stable batch runs.”

“ANCA already has our Tool Tip Tuesdays, monthly newsletter, The ANCA Club, face to face training, social media and YouTube channel, but we think there is so much to learn about our technology that we decided to start our own dedicated TV show. Make sure you send in any ideas or topic suggestions because this show is entirely dedicated to help our customers get even more out of their investment in ANCA. That way we both succeed.”

“The first episode covers the fundamentals of these types of collet adaptors, what makes them unique and how with some simple tricks, you can reduce your setup time and increase your productivity. After watching this episode, you will be able to confidently set up your ANCA PCA for reduced radial and axial runout and enjoy the benefits of long and stable batches.”

“If you have a brand new or an older ANCA machine and want to get right into accurate and repeatable grinding, then you definitely don’t want to miss this.”

Topics covered will include:

• Learn about clamping force

• PCA adaptors

• Mounting the collet

• Adjusting radial runout

To sign up the ANCA newsletter and don’t miss an episode, visit https://machines.anca.com/E-Sharp-News/Sign-up

Contact Details

Related Glossary Terms

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.