CNC machine tool spindles are essential to any drilling, milling, boring, grinding, routing, cutting, or sawing process, and many manufacturers and machine shops rely on rebuilders to get production back online as quickly as possible when problems arise, and replacement is required. However, rebuilding a spindle is not always as simple as shipping off a problematic unit to have its parts replaced.

Every industry and shop floor has specific even unique factors that involve the materials machined, cut depths, required speeds, volumes, and precision for a range of applications. Failing to take these factors into account can lead to a host of unresolved issues that can degrade quality, consistency and productivity.

At times the problems can be subtle such as intermittent variability or a faint sound indicating an issue that even a routine rebuild will not sufficiently resolve. Sometimes the problem can be serious and immediate. That is when additional expertise is required.

To cost-effectively ensure superior outcomes for challenges the best spindle repair shops will provide a true problem-solving approach. This includes understanding all requirements of the application, consulting with the machine shop operators, and even utilizing some expert detective work.

“The goal is to machine high precision parts as soon as possible at the facilities I oversee. Because our operators run spindles at very high speeds, very fast I need to be a problem solver and want to work with [spindle rebuilder and] repair shops that can problem solve, says Eduardo Flores, maintenance manager at GAMMA Aerospace, a specialized, end-to-end provider of engineered airframe and flight components for leading original equipment manufacturers and Tier I suppliers in the aerospace and defense industries.

Problem solving boosts profitability

GAMMA Aerospace’s facilities in Mansfield, Texas; Gardena and Los Angeles, California; and Mexicali, Mexico manufacture a diverse offering of components utilizing advanced, in-house special processes that encompass machining, forming, assembly and wet chemical special processing.

As the maintenance manager of two facilities, Flores oversees the use of about 50 CNC machines in Gardena and about 35 in Mexicali. His role is to keep the facilities efficiently running and involves ordering parts, troubleshooting, and problem-solving.

According to Flores, optimizing spindle reliability including repairs and rebuilds is the “bread and butter of the business” even when using softer metals like aluminum.

While diligently following preventative maintenance schedules for the CNC machines, Flores seeks expert help when concerns emerge. “Once the spindle starts giving us individual problems that is something I do not specialize in – so I consult with experts because I cannot fix everything despite my best efforts,” said Flores.

According to Flores, one specific brand of CNC machine had a unique situation where the spindles on a couple of units lost orientation.

“This was something we didn’t hear and didn’t see on the controller. We just saw the result when it was trying to do an automatic tool change. With the wrong orientation the automatic tool changer would jam,” says Flores. “The spindle certainly wasn’t bad; it was spinning correctly. It was just flipping on the orientation and was an OEM defect.”

According to Flores, neither reaching out to the spindle manufacturer nor the CNC machine OEM was helpful.

Instead, Flores turned to MZI Precision of Huntington Beach, Calif., an experienced machine tool spindle rebuilder. He consulted with Ed Zitney, President of MZI Precision who observed the machine and saw that it was slipping. He took the spindle and created a retrofit for it.

Zitney explained that in these cases, the spindle would lose its location about the tool changer, which is typically a proximity switch issue. “We tested the proximity sensor, examined the location settings, the gap, and looked for any damage on the spindle’s pickup diameter or the sensor,” he said.

“We discovered that all the proximity components were in good working order, but that on this particular model of spindle the compression rings were not capable of holding the coupling 100% in place. It would turn slightly, causing the machine controls to see a loss of positioning,” said Zitney.

Utilizing all OEM components, MZI Precision engineered four pins that would locate and lock the coupling in place. This eliminated the movement and solved the issue of the machine faulting out because of the lost position.

According to Flores, the retrofit quickly and cost-effectively resolved the spindle problem, facilitating tool changes.

“The engineered pins lock the spindle in place. It does not slip and lose its orientation, so tool changes are easy,” says Flores. He pointed out the significant impact on production and the bottom line.

“Purchasing a new spindle would have cost us ten thousand dollars plus about a thousand dollars to expedite it air freight from Taiwan and may not have solved the problem because it was an OEM design issue,” says Flores. “For the same reason, a rebuild alone probably would not have resolved it. Working with an expert [MZI Precision] we ended up saving thousands of dollars per machine for a critical retrofit that will help us keep six CNC machines reliably operating going forward.”

Solving a mystery

While CNC machining is all about high precision and high production, sometimes when the unexpected occurs with the equipment it can take the problem-solving mindset of a detective to track down the culprit and put things right.

“We cannot afford to have a CNC machine not producing with unscheduled downtime,” says Jon Welci, production manager at a Southern California production site of Lexani Wheel Corp, a global manufacturer of custom luxury wheels.

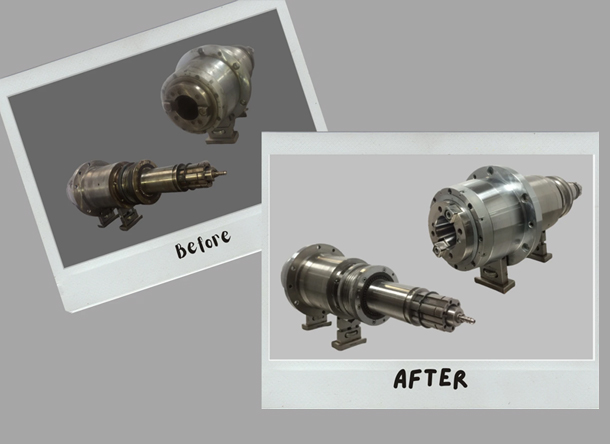

According to Welci he currently oversees about 15 CNC machines in his shop, and most are relatively new. When MZI Precision rebuilt the spindle of an older machine to OEM specification, however, within a few days after installation the grease had mysteriously washed out of the bearings, posing a performance hazard.

When MZI Precision investigated onsite its technicians found that the vertical milling spindle was driven by a gearbox filled with oil, and oil from the gearbox had overflowed into the top end of the spindle.

“The spindle design did not have a proper seal to restrict the oil from entering the spindle, so the oil displaced the bearing grease. The bearings ran very hot in the oil and would burn up very quickly,” explains Zitney.

According to Zitney, the fix was to engineer and manufacture a new top-end cover/slinger. This new part covers the top end of the spindle and rotates with the spindle when running, preventing oil from entering the spindle’s top.

For even greater reliability and performance, Welci ‘s shop upgraded to ceramic hybrid bearings in the spindle at MZI Precision’s recommendation. With the engineered changes and the upgraded bearings, the problem is solved. The spindle is far better outfitted for reliable performance than the OEM-supplied unit.

“The CNC machine now works great. The increased reliability and performance make a big difference in our business,” concluded Welch.

When manufacturers and machine shops attempt to achieve a little more production uptime, precision and performance from their equipment, relying on a partner with deep spindle expertise can be the difference that truly increases their competitiveness and profitability.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- sawing

sawing

Machining operation in which a powered machine, usually equipped with a blade having milled or ground teeth, is used to part material (cutoff) or give it a new shape (contour bandsawing, band machining). Four basic types of sawing operations are: hacksawing (power or manual operation in which the blade moves back and forth through the work, cutting on one of the strokes); cold or circular sawing (a rotating, circular, toothed blade parts the material much as a workshop table saw or radial-arm saw cuts wood); bandsawing (a flexible, toothed blade rides on wheels under tension and is guided through the work); and abrasive sawing (abrasive points attached to a fiber or metal backing part stock, could be considered a grinding operation).

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).