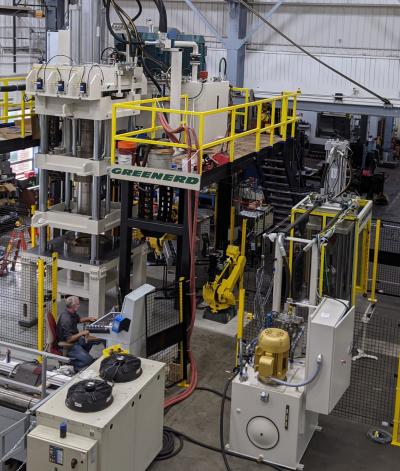

Greenerd Press & Machine Company has announced it has designed, engineered, built and turnkey-installed an automated two-press, two-robot production cell enabling unattended production of large aluminum pressure vessels.

Using sensors to locate pallets of blanks that have been placed in a pallet staging area, the first FANUC robot picks a blank, detects and rejects any double-blanks, and transfers the blank to a fully integrated and automated blank lube station. That robot then picks a previously lubricated blank and loads it into a Greenerd deep-draw press with a 76-inch stroke.

A second FANUC robot then catches and transfers the formed parts to a second Greenerd press for a punching operation. The two-press production cell uses a centralized control station which sets the operating parameters of both presses and controls the action sequences of both FANUC robots. All equipment in the cell is automatically updated with new process parameters when changing between products.

Greenerd provides unique hydraulic press automation solutions for a wide range of industries and applications. "Increasingly, our customers are seeking turnkey, state-of-the-art robotics and other product handling solutions. To meet the demands of today's challenging applications, we are providing manufacturers with automated press solutions that are flexible, productive and reliable," commented Greenerd Press & Machine Company’s President and CEO, Mr. Jerry Letendre.

Contact Details

Related Glossary Terms

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.