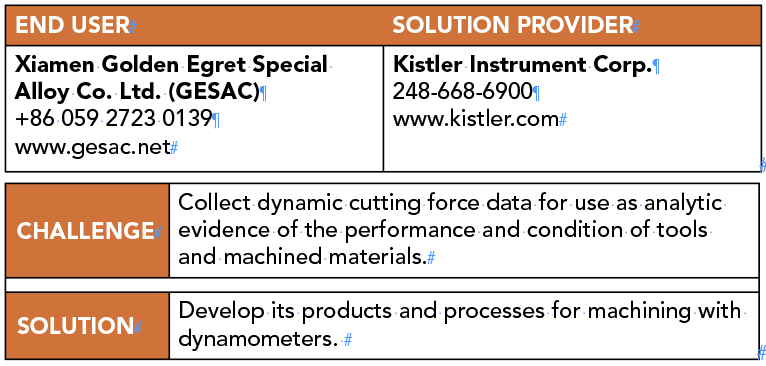

To develop and refine its machining tools, cutting tool manufacturer Xiamen Golden Egret Special Alloy Co. Ltd. (GESAC) works with piezoelectric dynamometers from the Kistler Group, including the new wireless rotating cutting dynamometer from the Kistler Instrument Corp. in Novi, Michigan.

With the precise measurement data, GESAC’s customers benefit from detailed performance comparisons between different tools and application-specific solutions such as advanced drill bits.

As industry has become more digitally connected over the last decade, machining centers have been able to leverage improved automation technologies. Machining centers equipped with CNC, sensors and advanced transmission technologies ensure efficient production with high precision, speed and quality. Cutting tools, as consumables, have always played a critical role in these changes: their qualities — or more specifically, their precision, durability, stability and applicability — ultimately determine the performance and cost-effectiveness of machined parts.

Located in Xiamen, China, GESAC was launched in 1989 with joint funding from Chinese and foreign investors. Since 2004, the Cutting Tools Div. at GESAC has focused intensively on cutting tool R&D. As a backbone member of Xiamen Tungsten Co. Ltd. (XTC), GESAC has set up a number of manufacturing bases and technical sales centers in China, Brazil, Japan, Germany and Thailand.

“Tool R&D requires great learning efforts, and it has to overcome major technological barriers,” said Lin Liangliang, R&D director of the Cutting Tools Div. “Tools play a decisive part in machining quality, but they are also consumables that are sensitive to unit costs. In that way, they differ from many other industrial products.”

This makes it essential to evaluate tool properties in relation to downstream customer-specific machining scenarios.

A successful R&D process requires measurement systems that can collect dynamic cutting force data for use as analytic evidence of the performance and condition of tools and machined materials. To meet this need, GESAC opted for dynamic measurement products from Kistler.

“Aided by our collaboration alliances with various Chinese universities, and based on recommendations from professors and industry experts, we launched our trials of Kistler products in 2009. We’ve now been using dynamometers from Kistler in our R&D for over 10 years,” said Zhao Biaochun, manager of product testing and analysis at GESAC.

The toolmaker focuses on three main product categories: solid-carbide endmills, indexable cutting tools and drills. Samples of all products in each category must undergo testing of properties and durability, as well as tests under working conditions at the end of the manufacturing process.

“Measurement results acquired with Kistler dynamometers have improved our ability to assess tools, especially drill bits, given that our previous approach was not sufficiently objective,” Zhao added.

Unlike turning and milling, chip removal when drilling occurs inside the tool, so it cannot easily be seen during machining. Previously, experienced technicians used to base their speculations about the progress of chip removal on the noises made by a machine tool and its load, but such assessments were highly subjective and uncertain. Now, with the help of cutting force dynamometers, the engineers at GESAC can accurately measure the force indexes of a running drill bit and observe the subtle changes that take place in them.

Zhao concludes: “Dynamometers from Kistler provide wide, high-precision measuring ranges. The assured quality of these products is one of the main reasons for our long-term partnership.”

Thanks to measurement data acquisition with Kistler solutions, GESAC is also able to perform in-depth tool comparisons. For example, if a conventional twist drill is used to machine a thin-walled aluminum alloy part for use in the aviation industry, the part can easily be deformed. By analyzing accuracy errors when drilling thin-walled workpieces, the R&D team at GESAC learned that cantilever deformation is directly related to cutting forces: smaller cutting forces mean smaller deformation and more precise hole sizes. A trepanning drill, on the other hand, has two innate advantages. First, its tool edges are subject to less disturbance from cutting chips during machining. Second, it applies smaller cutting forces. To compare how the two different drilling tools perform when machining thin-walled parts, the team analyzed the cutting force data collected with dynamometers from Kistler. The results show that trepanning drills apply significantly smaller cutting forces than twist drills, and they can deliver a much finer surface quality for the machined parts.

GESAC was also among the first customers to try the new wireless rotating cutting dynamometer (RCD) from Kistler. Thanks to this innovation, customers can transmit the measured cutting forces directly to their PC via wireless signal receivers, eliminating the intricate cable connections previously needed inside the machines. Like conventional rotating dynamometers, the wireless RCD (Type 9170B) offers advantages such as high natural frequency, a wide measuring range and the ability to measure real-time cutting forces through a rotating tool range. During the measurement, this dynamometer can immediately output the values of Fx, Fy, Fz and Mz, and then display the tangential force (Ft) and normal force (Fn) thanks to software calculations.

“We can even match measured data directly to the individual cutting edges of the corresponding tools. That allows us to determine the specific forces applied on each edge exactly, so we can use them more appropriately,” explained Liangliang of GESAC’s Cutting Tool Div.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- cutting force

cutting force

Engagement of a tool’s cutting edge with a workpiece generates a cutting force. Such a cutting force combines tangential, feed and radial forces, which can be measured by a dynamometer. Of the three cutting force components, tangential force is the greatest. Tangential force generates torque and accounts for more than 95 percent of the machining power. See dynamometer.

- dynamometer

dynamometer

When drilling, a device for measuring the generated torque and axial force (thrust). When milling, a device for measuring the generated torque and feed force. When turning, a device for measuring the tangential, feed and radial forces.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- trepanning

trepanning

Drilling deep holes that are too large to be drilled by high-pressure coolant drills or gundrills. Trepanning generates a solid core and normally requires a big, powerful machine. Shallow trepanning operations can be performed on modified engine or turret lathes or on boring machines. See boring; drilling; spade drilling.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- twist drill

twist drill

Most common type of drill, having two or more cutting edges, and having helical grooves adjacent thereto for the passage of chips and for admitting coolant to the cutting edges. Twist drills are used either for originating holes or for enlarging existing holes. Standard twist drills come in fractional sizes from 1¼16" to 11¼2", wire-gage sizes from 1 to 80, letter sizes A to Z and metric sizes.