DarkAero, an aerospace company based in Madison, Wisconsin, is on a mission to revolutionize personal aviation.

Established by the visionary trio of brothers – Keegan, River, and Ryley Karl – DarkAero combines cutting-edge engineering and sophisticated manufacturing practices to turn their collective vision into reality. Central to its manufacturing process is the Tormach 1500MX CNC Mill, which has become an indispensable tool in the company’s intricate production and prototyping efforts.

DarkAero’s ambitious vision

DarkAero -- which aims to make aviation more accessible and efficient by providing cutting-edge aircraft kits that enthusiasts and builders can assemble- is developing an experimental aircraft designed for speed, long-range travel, and efficiency. The Karl brothers’ mechanical, aerospace, and electrical engineering backgrounds have uniquely positioned them to innovate in this space.

The company is redefining personal aviation by offering aircraft in kit form, with an emphasis on components that are lightweight and ready for assembly, without overly complex requirements. Leveraging multiple Tormach machines, DarkAero not only prototypes but also manufactures these critical parts. This approach emphasizes design for manufacturability, ensuring components are manageable to produce and assemble.

The company is redefining personal aviation by offering aircraft in kit form, with an emphasis on components that are lightweight and ready for assembly, without overly complex requirements. Leveraging multiple Tormach machines, DarkAero not only prototypes but also manufactures these critical parts. This approach emphasizes design for manufacturability, ensuring components are manageable to produce and assemble.

“What we’re doing at DarkAero is developing a high-performance aircraft kit that combines lightweight composite materials with precision-engineered metal components,” said Keegan Karl, co-founder and vice president of DarkAero. “We’re now transitioning from the prototyping stage into flight testing and production activities. Throughout the whole process, we have been using Tormach equipment, including the 1100 PCNC and now our newest model, the 1500MX.”

Impact of Tormach 1500MX

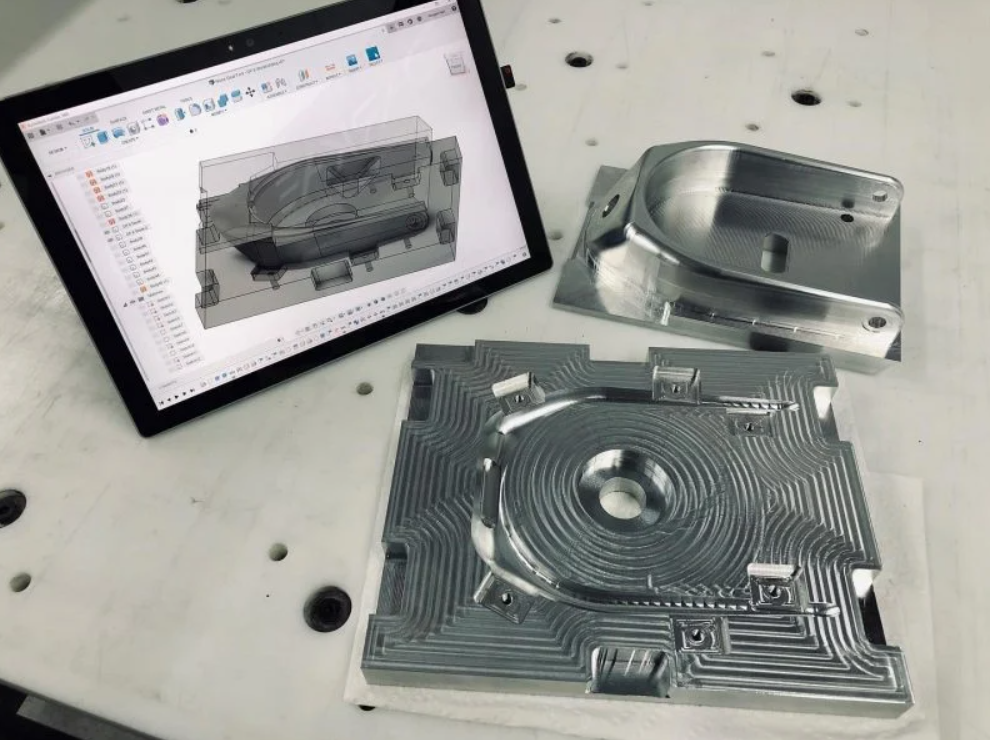

The potential for complexity in manufacturing and assembly poses a significant challenge for any aerospace company. To mitigate these risks, DarkAero capitalizes on its capacity to prototype inexpensively in-house, utilizing Tormach machines to craft authentic, production-ready aerospace parts. This strategy ensures a smooth, efficient manufacturing process that aligns with its innovative business model.

The Tormach 1500MX has been a game-changer for DarkAero as the new machine’s capabilities have drastically improved workflow, especially in terms of production readiness and precision.

The Tormach 1500MX has been a game-changer for DarkAero as the new machine’s capabilities have drastically improved workflow, especially in terms of production readiness and precision.

“We were really excited to have the very first 1500MX unit in our shop to test out and see what it’s capable of,” said Karl. “We learned quickly that this machine is extremely capable. The spindle can go up to 10,000 RPM. It also has rapid movements of 1,200 inches per minute for X and Y, and 600 inches per minute for Z, which means it has a greater rate of material removal than the previous model.”

One of the standout features of the new Tormach 1500MX is its large machining envelope, which allows for the creation of bigger parts. This is crucial for DarkAero as it transitions from prototyping to production. The machine also includes through-spindle coolant and a washdown feature, significantly reducing the manual cleanup and setup time.

“On the 1500MX, the coolant comes out of the spindle head and can go through the tools, which helps in reducing tool wear, improving cutting efficiency and maintaining tighter tolerances on the machined parts,” added Karl. “It also has a washdown feature that takes all the chips generated during the machining process and funnels them into a collection unit at the back. This is a huge upgrade from what we had before.”

Impact on production

When it comes to production, the new Tormach 1500MX has allowed DarkAero to streamline its manufacturing process, making it more efficient and less error prone. The machine’s automatic tool changer and built-in camera for monitoring crashes are just a few of the features that enhance its usability and reliability.

“The automatic tool changer is a significant time-saver,” Karl explained. “You can upload your program, hit go, and then walk away to get other things done without worrying about chip evacuation or changing out tools. The built-in camera records any emergency stop events, helping us diagnose problems quickly.”

“The automatic tool changer is a significant time-saver,” Karl explained. “You can upload your program, hit go, and then walk away to get other things done without worrying about chip evacuation or changing out tools. The built-in camera records any emergency stop events, helping us diagnose problems quickly.”

The ability to prototype and produce parts in-house has been a crucial advantage for DarkAero. It allows the company to rapidly iterate on designs and make improvements without the delays associated with outsourcing. This flexibility is especially important in the dynamic field of aircraft design.

“There are benefits to throwing it over the wall and outsourcing it sometimes, but if you have the capability to do it all under one roof, things can happen much more quickly,” says Karl. “We can make changes on the fly, update the CAM, and run with it. This tight feedback loop has been invaluable for us.”

Cutting-edge collaboration

DarkAero’s collaboration with Tormach and commitment to an in-house operation has enabled it to push the boundaries of what’s possible in personal aviation. The Tormach 1500MX CNC Mill has provided the precision, efficiency and flexibility needed to bring DarkAero’s innovative aircraft to life. As the company continues to develop and refine its designs, the partnership with Tormach will undoubtedly remain a cornerstone of its success.

“The Tormach 1500MX has really shown a high level of automation for us,” said Karl. “A lot of time previously spent on setup and cleanup is now heavily offloaded onto the machine. We’re quite excited and look forward to creating more parts and sharing more content about this incredible machine.”

“The Tormach 1500MX has really shown a high level of automation for us,” said Karl. “A lot of time previously spent on setup and cleanup is now heavily offloaded onto the machine. We’re quite excited and look forward to creating more parts and sharing more content about this incredible machine.”

By leveraging the capabilities of the Tormach 1500MX, DarkAero is not only building a revolutionary aircraft but also redefining the possibilities of what a small, dedicated team can achieve in the aerospace industry.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.