In the production of heavy equipment for construction, forestry, mining and other industries, a variety of metals are used based on the performance requirements of the end-use application. These metals can range from carbon alloys used for strength and structural integrity to lightweight metals like aluminum and stainless steel, which provide corrosion resistance. Managing these materials in different metalworking applications, such as rolling, bending, forging, milling, grinding and drilling, is key to the manufacturer’s overall efficiency and profitability.

The industrial process fluid that enables operation is critical to these metalworking applications. A particular metalworking operation is only as good as how well its process fluid, also known as “metalworking fluid,” is managed.

Metalworking fluids typically provide three main functions: lubrication to remove friction between a tool and the workpiece, cooling to remove generated heat, and/or flushing to remove metal chips and fines.

In the case of coolants, many are water-soluble and applied as emulsions with a particular ideal concentration. Because concentration can vary due to natural evaporation or discharge, careful monitoring is recommended. Not maintaining optimal fluid concentration can lead to various problems, such as overconsumption of coolant, tool breakages, part defects, corrosion and even health and safety issues.

Though heavy equipment manufacturers have automated many parts of their manufacturing process, often the monitoring of metalworking fluid is done manually via regular collection of samples that are either sent to a laboratory for further analysis or are tested at the point of use with simple instruments like a refractometer. The labor effort for sampling alone can be significant. By the time laboratory analysis is completed, system conditions have changed. Alternatively, if an analog refractometer is used, human error can be introduced. Even when readings are accurate, replenishing fluid is still necessary to correct the concentration, a process which is often done manually.

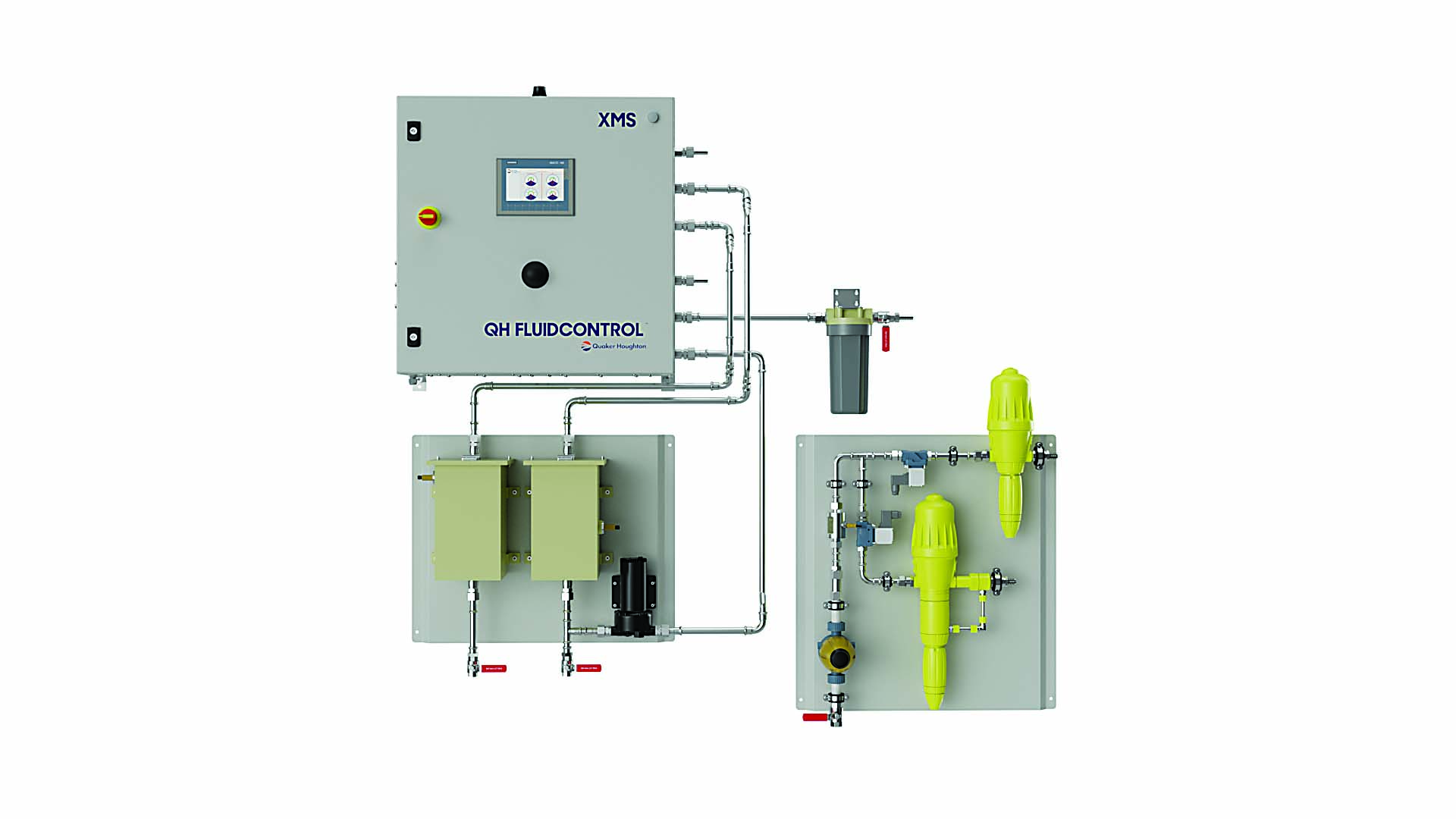

While some companies and suppliers have offered hardware to perform some fluid measurement or control, most have varying degrees of practicability and reliability, or have not been built to deliver significant and useful insights. Some industrial process fluid leaders have made significant progress in introducing complete automation and control technologies for digitally optimizing fluids and processes. For example, Conshohocken, Pennsylvania-headquartered Quaker Houghton has partnered with end users to understand customer needs in fluid management, like a fully automated hardware solution that is customizable, scalable and easily integrated into the manufacturing system, paired with user-friendly software giving real-time, accurate and actionable insights.

A significant Quaker Houghton investment has enabled trialing various sensors and control technologies in numerous fluid applications. The experience and knowledge gained has evolved into the QH Fluid Intelligence platform. This digital platform, which includes hardware customized to the company’s fluids and proprietary software for real-time continuous monitoring, control and data analytics, combines all the elements necessary to allow manufacturers to optimize fluid management. By digitally optimizing processes, manufacturers can refocus resources on their core business of efficiently producing high-quality, competitive products.

Like many manufacturing sectors, the heavy equipment manufacturing sector is challenged with improving quality, increasing efficiency and lowering costs to stay competitive. A top OEM of heavy equipment for the agricultural industry was facing challenges with coolant stability in its grinding operations. Poor fluid management practices led to bacteria and fungi, making coolant used in a critical gear tooth face grinding operation unstable. Poor coolant performance led to increased scrap, maintenance and production costs. The coolant delivery system piping had to be manually cleaned out, which consumed five days of production time every quarter.

The OEM contacted Quaker Houghton for a solution. Quaker Houghton recharged the OEM’s grinding system with a fully synthetic coolant and deployed its digital platform, including hardware to automatically control the coolant system and software to provide real-time data logging and analysis. Using this platform, the OEM reduced operational costs by about $300,000 annually and decreased machine downtime by 75%, equivalent to over 1,000 hours of additional productive time per year. The now stable and controlled coolant environment enhanced production efficiency, increased output and reduced costs.

For more information about Quaker Houghton, call 610-832-4000 or visit www.quakerhoughton.com.

—Quaker Houghton

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- corrosion resistance

corrosion resistance

Ability of an alloy or material to withstand rust and corrosion. These are properties fostered by nickel and chromium in alloys such as stainless steel.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- refractometer

refractometer

Optical instrument that measures the refractive index of a liquid, such as a water-diluted metalworking fluid mix. The refractive index can by used to determine the concentration of a fresh metalworking fluid mix.