Sphero High-Precision Tool Machine

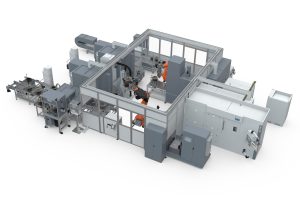

The workpiece unit is mounted vertically and easily accessible for fast changeover. Thanks to the integrated tool changer with a capacity for up to ten tools, even complex machining processes can be carried out in only one clamping process. The machine can be equipped with QuattroClean CO2 snow-jet technology, which enables the workpieces to be cleaned using an environmentally friendly, dry and residue-free method. After cleaning, the machined component is subjected to a scattered light measurement procedure that allows, e.g., the shape or the gloss value to be precisely determined. If a measurement value is not yet satisfactory, the component can then be put through another machining step in the same clamping procedure.

.jpg)

-scaled-225x300.jpg)