Products

•

August 26, 2019

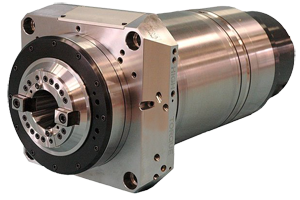

High-Speed Spindle Repair Service

In today's booming manufacturing environment, high machine tool utilization rates can have an impact on optimal machine tool performance resulting in planned or unplanned repair requirements. IBAG has stepped up its high-speed spindle repair and rebuilding services at their North Haven, Connecticut, facility. The comprehensive service includes a thorough spindle condition evaluation, analysis of all internal parts prior to approval for repair and rebuilding.