Contact Details

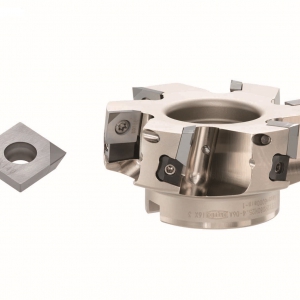

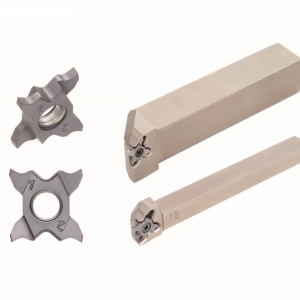

Tungaloy has introduced AddDoFeed small diameter high feed milling cutter series in diameters ranging from 8 to 25 mm (5/16″ to 1″).

AddDoFeed offers high feed milling capability for small parts machining, with the same cost efficiency and high productivity benefits of the renowned DoFeed solutions that have been around for over a decade.

Solid carbide end mills are a common approach for milling small parts. However, for slotting or pocketing applications that remove relatively large volume of stock, it is unproductive to use these small diameter solid end mills. Due to their low bending stiffness, the tool body cannot sustain the heavy radial force generated when feed is increased in an effort to gain better cycle time.

AddDoFeed uses minimal Size 02 inserts of 4 mm (5/32″) inscribed circle and offers close pitch cutter bodies that boast unrivaled insert-per-diameter density for a small diameter indexable cutter. This allows a 16 mm (5/8″) diameter body to carry four inserts and 25 mm (1″) seven inserts for higher feed rates and increased productivity.

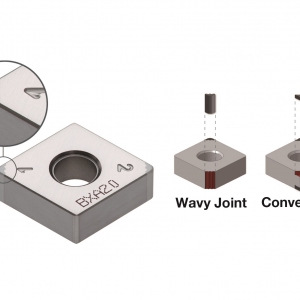

These tiny AddDoFeed02 inserts carry all key features that the DoFeed insert has been delivering, including economical double-sided insert with four effective cutting edges, optimal inclination on the cutting edge that enables smooth chip evacuation, and large positive rake that provides light cutting and process security. All these features make AddDoFeed an extremely productive solution for machining small parts in various material groups.

The new AddDoFeed products complement and empower Tungaloy’s existing high feed milling concepts. 21 new items of small sized and close pitch cutters are now available in addition to the current DoFeed series of medium diameter cutter range represented by Size 03 inserts and large diameter range with Size 06 inserts. The cutter series is now a highly productive solution, over more extensive application areas, in various materials groups.

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- inscribed circle ( IC)

inscribed circle ( IC)

Imaginary circle that touches all sides of an insert. Used to establish size. Measurements are in fractions of an inch and describe the diameter of the circle.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.

PRODUCTS

PRODUCTS