Contact Details

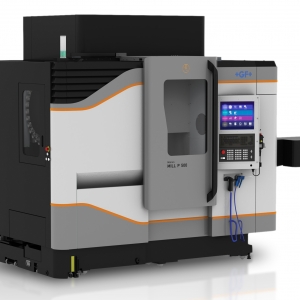

GF Machining Solutions announces the availability of its AgieCharmilles CUT C 350 and CUT C 600 wire EDMs for U.S. manufacturers that want high performance with low operating costs. At a $99,000 starting price point, the machines are not only cost-effective, but also provide optimized cutting speeds and reliable accuracy, while their AC CUT HMI 2 systems make for easy programming through efficient EDM expert modules.

Both the CUT C 350 and CUT C 600 offer manual mode setup for access to main functions that enable operators to perform manual measurements and machining. The machines feature low-maintenance designs that use minimal components and consumable parts to reduce operating costs. Along with an integrated anti-collision protection system, the machines include linear glass scales and encoders for high production accuracy.

Easily accessible wire spool holders allow for fast and easy changes, and standard automatic threading systems thread hard, soft, coated or uncoated wire for reliable lights-out manufacturing.

Both the CUT C 350 and CUT C 600 operate with digital Intelligent Power Generators (IPG) for optimized cutting speeds and feature several Expert Intelligent technologies to manage surface quality and part precision while they streamline overall operation. With IPG, the machines generate surface finishes of 0.25µm Ra in carbide and 0.30µm Ra in steel.

For wire breakage prevention on variable-height parts, the POWER-EXPERT intelligent function automatically selects optimal power levels. Corner-cutting strategies automatically adjust machining parameters during changes of cutting direction to create accurate sharp angles and small radii.

File and project management intelligent features on the CUT C 350 and CUT C 600 enable operators to configure and sequence jobs, follow job progress, manage digital project documents and access the AC CAM EASY programming system for autonomous operation.

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

PRODUCTS

PRODUCTS