Contact Details

Tungaloy is expanding TurnTen-Feed to include a new insert grade, AH8015, for efficient medium-to-heavy turning of heat-resistant alloys and stainless steel.

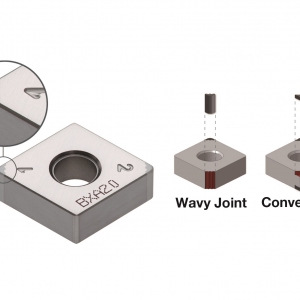

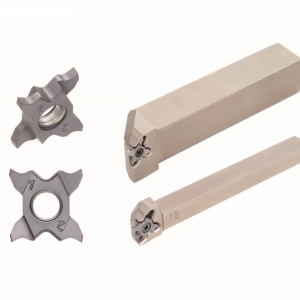

TurnTen-Feed incorporates a cost-effective double-sided insert with 10 cutting edges, which is securely clamped on the holder with a Dovetail interlock to ensure high insert reliability and stability during demanding medium-to-heavy turning operations. The dedicated -MNW geometry is designed to provide smooth chip flow when fed at a rate as high as 2.0 mm per rev (.078 ipr) without sacrificing surface integrity thanks to the built-in wiper flat.

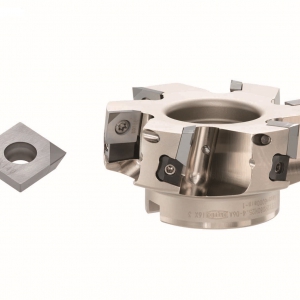

Two types of holders are available extending its application options: the HD (High Depth-of-cut) holder for greater depths-of-cut of up to 7.0 mm and HF (High Feed) holder which enables high feed turning of up to 2.0 mm per rev. These 2 types of holders can accommodate either type of insert.

The AH8015 grade consists of a nano-structured multilayer PVD coating with high aluminum content. Its exceptional wear and fracture resistance contributes to process security during machining of heat-resistant alloys and stainless steel as well as significantly boosts productivity in heavy-duty roughing of difficult materials and large components.

At a Glance:

Provides high efficiency in machining difficult-to-cut materials thanks to exceptional wear and fracture resistance of AH8015

Ten-edged double-sided insert clamped with a Dovetail interlock assures cost-effectiveness and process security

MNW geometry provides effective chip control during medium-to-heavy turning operations

Built-in wiper flat ensures surface integrity at high feed rates

Two types of turning holders extend application options

Two inserts to be introduced in this expansion

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS