AVD 300 Parts Washer

AVD 300 Parts Washer

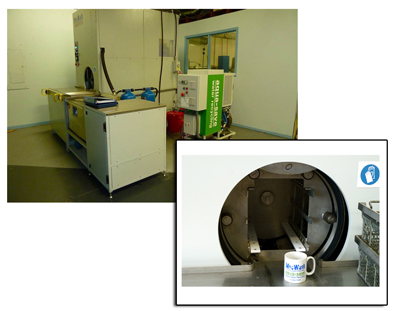

MecWash Systems introduces the AVD 300 aqueous parts washer for complex and intricate machined or stamped parts that require high standards of cleanliness, surface finish, and drying, including defense, aerospace and medical components.

MecWash Systems introduces the AVD 300 aqueous parts washer for complex and intricate machined or stamped parts that require high standards of cleanliness, surface finish, and drying, including defense, aerospace and medical components. This compact, fully automatic and self-contained aqueous cleaning system removes all types of contamination including soluble and mineral oils or greases, polishing compounds, lapping paste, and NDT dye penetrants from sensitive alloys and other metals. The versatile AVD is capable of cleaning large components or dense baskets of small parts, with a compact design that is well suited for small volume, high precision machining cells. Designed for the highest-performance cleaning and drying of precision engineered components, the MecWash AVD is ideal for defense, medical, aerospace and industrial applications.

Ideal for cell-manufacturing or within a centralized layout, the AVD 300 measures just 4" (W) x 8" (D) x 8" (H), so it occupies a small footprint. This highly versatile single chamber rotational cleaning system features full immersion, spray, and ultrasonic wash, full immersion, spray, and ultrasonic. It also comes fitted with hot air dry as well as vacuum dry, if needed. Proven MecWash aqueous technology cleans without solvents or emissions, and is effective cleaning both large and small components in purpose-built fixtures or standard size stainless steel baskets and plastic totes.

The AVD wash chamber includes dozens of high volume jets that thoroughly penetrate and saturate the workload at over 100 gallons per minute. The temperature of both the wash and rinse waters can be set at the operator's discretion between 140 degrees to 190°F. Full rotation of the workload at from 2-10 rpm exposes all surfaces and deep machined passageways to the wash and rinse solutions to ensure effective cleaning, draining, and drying. Alternately, for parts with delicate geometries, the AVD can be programmed to gently oscillate from side to side.

The unit's ultrasonic flood, standard flood, and spray wash cycles are followed by an ultrasonic flood, standard flood, and spray rinse cycle. Afterward, a high velocity blow dryer raises temperature up to 250°F to quickly dry all faces of the given components' surfaces as they rotate or oscillate during the dry cycle. For components that have blind holes whereby water is retained due to capillary effect, a vacuum drying feature is also available for installation on the AVD. And for those companies manufacturing in iron and steel, MecWash manufactures a complete line of aqueous cleaning chemicals with corrosion inhibition, which serves to protect these iron and steel components from rust for up to two weeks after aqueous cleaning.