Contact Details

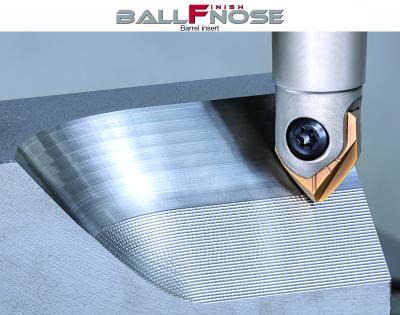

Tungaloy has expanded its BallFinishNose indexable tool capabilities of profiling complex 3D contours by adding five “barrel” style inserts for improved cycle time reduction in contoured workpieces.

BallFinishNose is an effective tool in finishing and semi-finishing, particularly on geometric surfaces and complex 3D contours common to die-mold or aerospace applications. The insert features a unique asymmetric shape. This design allows users to use the same side of the insert always facing the same direction when set in the tool body, providing the tool with high repeatable accuracy and reliability, surface quality and predictable tool life.

Tungaloy has added five barrel style inserts to BallFinishNose to increase its efficiency of 3D profile milling capability. The barrel inserts, so named after the resemblance of the cutting edge shape to a barrel’s profile, consist of cutting edges with larger radii compared with ball nose endmills, creating greater contact between the cutting edge and workpiece. This permits larger stepover increments, maximizing efficiency without compromising on cusp heights and enables the removal of more material with fewer passes.

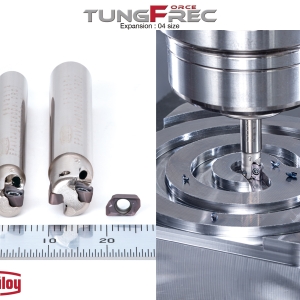

The barrel style inserts can be used with existing BallFinishNose cutter bodies. The inserts are designed to fit the cutter bodies in diameters ranging from 12 to 30 millimeters (from .472 to 1.181 inches). The barrel style inserts’ cutting edge radii are available in 30, 40, 50, 62.5, and 75 millimeters, and each set of inserts fit the cutter in diameters 12, 16, 20, 25, and 30 millimeters, respectively.

Featuring the coolant channels on the insert faces just as those on existing BallFinishNose inserts, the barrel style inserts ensure optimal coolant delivery close to the cutting area, providing stable and long tool life.

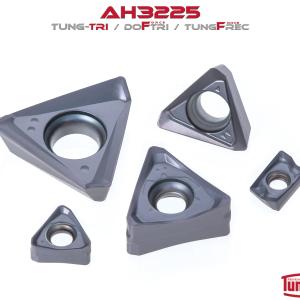

The barrel style inserts are offered in CH315 insert grade. A combination of extreme wear resistance made possible by the latest PVD coating technology and fracture resistant dedicated carbide substrate, the latest CH315 provides the insert with exceptionally long tool life.

With the new barrel style inserts in the line, BallFinishNose lends itself to finish machining of 3D complex surfaces and other intricate profiles typical in die-mold and aerospace segments.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS