Contact Details

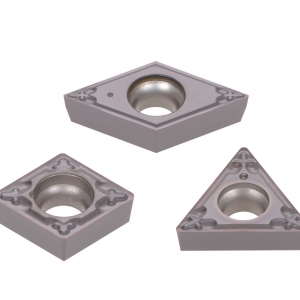

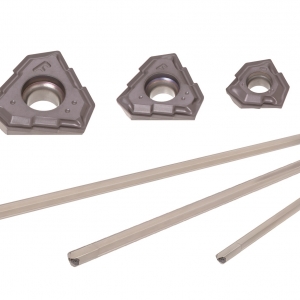

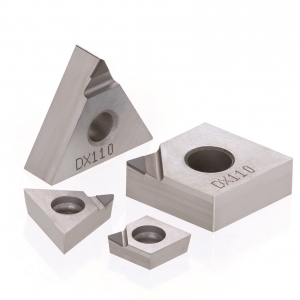

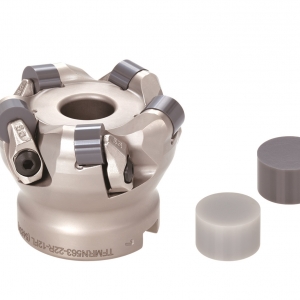

Tungaloy Corp. is launching the BXA20 series, a new coated PCBN grade for machining hardened steel. BXA20 delivers predictable and long tool life in a range of applications from roughing to finishing, including descaling of case hardened steel, which usually requires a large stock to be removed. This PCBN grade exhibits excellent wear and fracture resistance in a low to medium cutting speed range, with enhanced tool life in continuous as well as interrupted cuts.

The BXA20 series is available with a built in wiper for a superb surface finish at high feed rates or a chipbreaker for smooth chip control in large stock removal, covering a wide variety of applications.

Main features:

BXA20’s multi-layered PVD coating is twice as thick as the conventional grade to improve wear resistance. The top most layer of the coating has a very low coefficient of friction to help reduce crater wear. This multilayered PVD coating with enhanced adhesion strength increases chipping and peel off resistances, thus assuring stable and long tool life.

The dedicated carbide substrate withstands a heavy load of interrupted cutting and large depth of cut machining.

With a bright silver finish, used corners can easily be identified.

Related Glossary Terms

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- polycrystalline cubic boron nitride ( PCBN)

polycrystalline cubic boron nitride ( PCBN)

Cutting tool material consisting of polycrystalline cubic boron nitride with a metallic or ceramic binder. PCBN is available either as a tip brazed to a carbide insert carrier or as a solid insert. Primarily used for cutting hardened ferrous alloys.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS