Contact Details

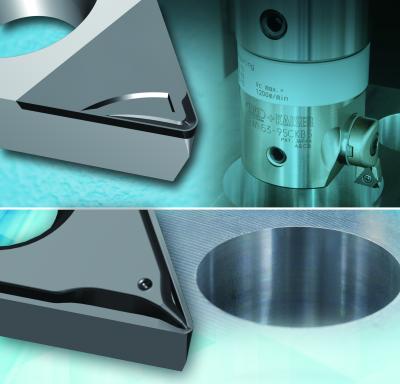

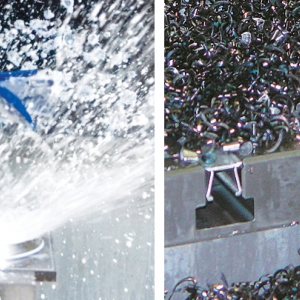

BIG KAISER Precision Tooling has released two new insert chip-breaker types designed to improve surface finish in long-chipping materials. Long chips that are difficult to evacuate can lead to poor surface finishes when chips are dragged around by the tool. Insert life can be severely reduced if these chips are re-cut by the insert, and in small-diameter applications stringy chips can wrap around the tool to the point where a crash occurs.

The exclusive FLM 3D chip-breaker design is used on PCD-tipped inserts ideal for finishing of aluminum components, where traditional flat-top inserts may produce a large continuous nest of chips that is difficult to remove from the bore and/or tool, even with high-pressure coolant. Three different radius options are available: .008”, .016” and .031” for the insert TCGT2 (1.5).

For finishing in mild- or construction steels, cermet inserts with chip-breaker form ELM should be used. Available in .008” radius and combined with a light depth of cut, this chip-breaker creates a high-shear angle to shorten the cutting chips for better evacuation and gives superior surface finishes in these traditionally difficult materials.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

PRODUCTS

PRODUCTS