Contact Details

BIG KAISER announces three additions to the Smart Damper family of antivibration technology: EWN & EWD finish boring heads and SW rough boring heads with the CKB modular connection. Smart Damper incorporates a passive damping mechanism that functions as a counter action by way of high resonance friction action. The patent-pending system’s damping capability minimizes the effects of high frequency oscillations, absorbing vibration effectively and allowing higher machining accuracy, according to the company.

The modular CKB connection allows for an array of standard shanks and extensions to be adapted with the heads to create “custom” tools to extend over 16 inches, maintaining damping near the cutting edge and managing vibration in long-overhang setups.

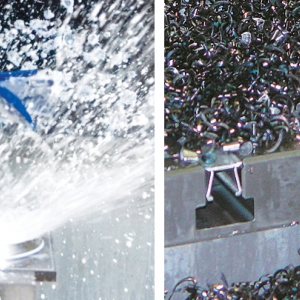

The heavy-duty SW twin-cutter head with integral Smart Damper, for rough boring holes 1.614” to 4.331” in diameter, efficiently creates deep bores into iron or steel workpieces quickly, quietly and most importantly without vibration or chatter. This means that faster machining and higher productivity rates are possible.

The SW Smart Damper can operate at cutting speeds of up to 660 sfm in steel at a length of 8xD without chattering. This is four times faster than the 165 sfm maximum chatterless cutting speed attainable with the standard SW heads.

Moreover, the SW Smart Damper can perform two roughing operations without needing to change any components due to individually adjustable insert holders with a unique design element. Balanced cutting for high speed operations where inserts are of the same diameter and length, and stepped cutting for high stock removal where the insert holders are simply reversed to create diameter and height offsets.

For finish boring, tests have shown that with the high-precision mid-size diameter boring head types EWN and EWD with Smart Damper technology, deep holes free of vibration can be bored with dramatic improvements in time and accuracy. For example, with a projection length of 16 inches and working in steel, a cutting speed of 1,500 sfm and feed rate of 6 ipm can be achieved.

The EWN analog heads feature .0005”/diameter setting accuracy, with .0001”/diameter possible with Vernier precision. EWD digital heads feature Ø.00005” setting accuracy, and have a seal rating of IP69K. The overall program between three head sizes covers the diameter range of 1.614” to 5.906”. Both head types are coolant-through, and thanks to three different insert holders per head, a wide range of diameters can be processed on each head. For example, between 2.677” and 5.906” for the EWD 68 Smart Damper.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring head

boring head

Single- or multiple-point precision tool used to bring an existing hole within dimensional tolerance. The head attaches to a standard toolholder and a mechanism permits fine adjustments to be made to the head within a diameter range.

- chatter

chatter

Condition of vibration involving the machine, workpiece and cutting tool. Once this condition arises, it is often self-sustaining until the problem is corrected. Chatter can be identified when lines or grooves appear at regular intervals in the workpiece. These lines or grooves are caused by the teeth of the cutter as they vibrate in and out of the workpiece and their spacing depends on the frequency of vibration.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

PRODUCTS

PRODUCTS