Contact Details

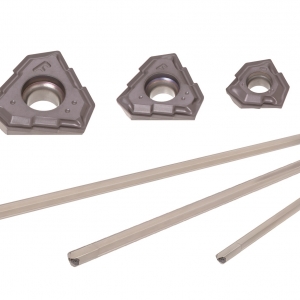

Tungaloy introduces a new line of collet chuck sleeves for the TinyMini-Turn miniature boring tool system, enabling a quick changeover of its solid-carbide boring bars.

TinyMini-Turn is a boring tool system consisting of solid carbide boring bars and sleeves, designed for high precision internal boring, grooving, and threading applications in extremely small diameters as small as 0.6 mm (0.024").

This new sleeve features an integrated collect chuck for precision clamping and repeatability as well as quick changeover of boring bars while the sleeve remains mounted in the tool post. A boring bar can easily be changed by operating the clamping cap equipped on the sleeve. In addition, the collet chuck provides full contact gripping on the boring bar shank for higher stability and repeatability over conventional bolt-clamp holders. The sleeve is capable of through-coolant supply for improved chip evacuation and tool life.

At a Glance:

Easy tool changeover

Clamping cap ensures easy changeover of boring bars

High repeatability

Collet chuck provides full contact gripping for higher indexing accuracy and repeatability

Easy coolant tube connection

R1/8 fitting threads is provided at the end of the sleeve for easy tube connection

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- boring bar

boring bar

Essentially a cantilever beam that holds one or more cutting tools in position during a boring operation. Can be held stationary and moved axially while the workpiece revolves around it, or revolved and moved axially while the workpiece is held stationary, or a combination of these actions. Installed on milling, drilling and boring machines, as well as lathes and machining centers.

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- collet

collet

Flexible-sided device that secures a tool or workpiece. Similar in function to a chuck, but can accommodate only a narrow size range. Typically provides greater gripping force and precision than a chuck. See chuck.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

PRODUCTS

PRODUCTS